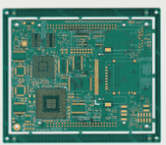

1. The PCB circuit design needed for embedded microcontrollers is a substantial undertaking. For advanced microcontrollers, data sheets and technical documents can easily exceed hundreds of pages.

2. Before initiating the circuit design, it’s advisable to create a flowchart illustrating the operation of all key components involved, including all peripheral devices interfacing with the microcontroller.

3. ARM Cortex-M microcontroller

4. This article will address the PCB design considerations necessary for integrating the ARM Cortex-M microcontroller. Various versions of ARM Cortex-M microcontrollers are offered by different chip manufacturers.

5. In comparison to standard 8-bit microcontrollers, the 32-bit architecture of ARM Cortex-M is particularly well-suited for demanding and computation-heavy tasks. Additionally, 32-bit microcontrollers provide advantages in applications requiring greater memory capacity or facilitating simpler system platform migration for future scalability.

6. The ARM Cortex-M microcontroller under discussion is the STM32 family produced by ST Microelectronics, with a specific focus on the STM32F4 series.

—

Let me know if you need any more adjustments!

1. The STM32 family encompasses various models, including the ultra-low power STM32L series and versions with both higher and lower performance compared to the STM32F4. The STM32F7 stands out as the most efficient, executing 1 billion instructions per second, while the STM32L0 ranks among the least efficient, processing only 26 million instructions per second.

2. Power supply design is a crucial aspect of hardware development; it’s essential to finalize the power supply and grounding configuration early in the design process, rather than waiting until later stages.

3. The microcontroller’s current consumption is influenced by several factors, including operating voltage, clock frequency, and the load on input/output pins.

4. To ensure effective power decoupling, place 1uF and 100nF ceramic capacitors (like C7 and C8 in Figure 1) as close as possible to each VDD pin on the MCU. Additionally, a 4.7uF ceramic capacitor (C1 in Figure 1) should be positioned near the IC on the main circuit wiring supplying VDD.

5. Microcontrollers equipped with analog-to-digital converters (ADC) typically feature independent power (VDDA) and ground pins (VSSA) specifically for analog signals, necessitating special care to minimize noise.

6. If your power supply voltage exceeds the microcontroller’s input voltage limit, a step-down linear regulator is usually required. The TPS795xx from Texas Instruments, for instance, offers exceptionally low noise and can deliver up to 500mA of current.

7. For significantly higher power supply voltages, a step-down switching regulator is more efficient, as linear regulators can waste excessive power when there’s a large input-output voltage differential.

8. It is often advantageous to use a linear regulator to sub-regulate the output of a switching regulator, as linear regulators produce much lower voltage noise.

9. The STM32F4 can operate with either an internal or external system clock. The internal clock (16 MHz) is used at startup, and after initialization, the external clock source can be selected via software.

10. The STM32F4 clock pin can support an external quartz crystal ranging from 4 to 26 MHz (see X1 in Figure 1) or can utilize an external clock source up to 50 MHz.

11. Crystal configuration must adhere strictly to the guidelines in the data sheet; generally, wiring should be kept short, and the load capacitance should match the values recommended by the crystal manufacturer.

12. The general-purpose input/output (GPIO) pins on the microcontroller are programmable and can be configured as input or output through software.

13. For instance, S1 in Figure 1 illustrates a button linked to a GPIO pin set as an input. STM32 incorporates a built-in pull-up resistor, negating the need for an external one, while the GPIO output drives an LED in this example.

14. Many GPIO pins also serve additional functions, allowing various peripheral components on the chip to communicate externally through these multifunctional pins.

15. Not all internal functions are accessible via every GPIO pin, so it’s essential to consult the data table when determining which pins to utilize.

16. GPIO pins can drive diverse loads, with most capable of supplying or tolerating up to 25mA. However, using an external drive circuit to alleviate the microcontroller’s GPIO load is generally a superior design choice; see Figure 1 for the example of MN1 driving LEDs.

17. Each STM32 pin has a specified current limit, alongside an overall limit for the total current across all GPIO pins.

18. STM32 facilitates serial signal connections via UART, I2C, SPI, and USB interfaces.

19. For example, Figure 1 depicts a temperature sensor (U2-LM75BDP) interfacing with the microcontroller through the I2C bus, requiring two pull-up resistors (R2, R3) for the open-drain driver.

20. For most low-speed sensor applications, I prefer I2C due to its simplicity, requiring only two wires for communication. Unlike SPI, which necessitates a separate chip select for each peripheral, I2C utilizes a single address.

21. The SPI bus connects to the MPU-9250 nine-axis motion sensor from Invensense, which integrates a three-axis accelerometer, gyroscope, and magnetometer.

22. The STM32F4 offers two in-system programming (ISP) interfaces: serial wire debugging (SWD) and JTAG. The more economical STM32 versions typically provide only the SWD interface, with both SWD and JTAG being the most widely used programming interfaces for microcontrollers.

23. In summary, this article explored PCB circuit design for microcontrollers, specifically highlighting the STM32F4’s capabilities in reading input buttons, driving LEDs, and communicating with I2C temperature sensors and SPI motion sensors.