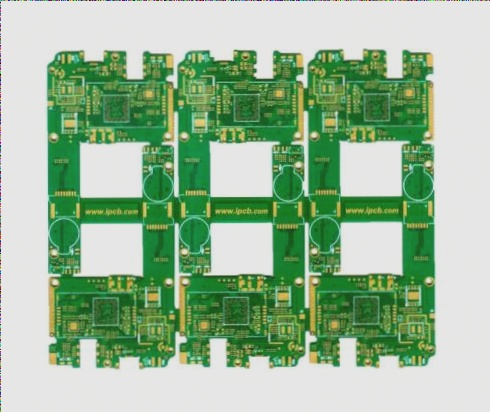

PCB Drilling: Essential Steps for Successful Component Placement

PCB drilling is a crucial process in creating rectangular holes on printed circuit boards (PCBs) to accommodate electronic components. This meticulous task ensures precise and straight holes with exact specifications, vital for seamless electronics assembly.

Understanding PCB Drilling Process

Drilling a PCB involves creating holes to fit components like transistors, resistors, and diodes. These holes are essential for connecting components and ensuring proper functionality of electronic devices. Without accurate drilling, the device may not operate efficiently.

Why PCB Drilling is Necessary

Drilling a PCB is a fundamental step in the manufacturing process, crucial for connecting electronic components effectively. The holes on the board facilitate communication between components, ensuring the device functions correctly.

Key Considerations Before Drilling

- Gain a basic understanding of PCB design and layout.

- Ensure you have the necessary tools, including a drilling bit and chuck.

- Familiarize yourself with the PCB design to make suitable modifications for component placement.

Types of PCB Drillers

- Sharp Drilling Machine:

The sharp drilling machine is ideal for drilling heavy materials like copper clad and aluminum.

- Tabletop Drilling Machine:

Best suited for drilling through PCBs made from lighter materials like FR-4 and Polyimide.

- Rotary Drilling Machine:

Rotary drilling machines offer a versatile drilling solution for various PCB materials.

PCB Drilling: A Comprehensive Guide

The rotary drilling machine is crucial for creating precise holes in materials like glass-fiber reinforced plastic, light wood, and more.

Steps to Successfully Drill a PCB

- Choose the right drilling machine:

Selecting the appropriate drilling machine is key. Consider factors like workpiece size, headstock length, bit size, and spindle speed for optimal results.

- Prepare the workpiece:

Properly prepare the workpiece to avoid PCB damage. Mill light materials or use sandpaper to remove contaminants from the surface.

- Set spindle speed and bit size:

Adjust spindle speed and bit size based on material thickness. Thick materials require higher speeds and larger bits, while light materials need smaller settings.

- Drill the PCB:

Once preparations are complete, begin drilling the PCB accurately.

Advantages of PCB Drilling

- Cost-effective: PCB manufacturers offer affordable solutions, making PCB drilling a budget-friendly option.

- Low risk: PCB drilling is a low-risk process, minimizing the chance of severe damage.

- Quick changeover: In emergencies, PCB drilling allows for swift replacement of damaged boards.

- Functional and eco-friendly: Drilled PCBs can be reused, utilizing recycled materials and benefiting the environment.

Precautions for PCB Drilling

To ensure a safe and successful drilling process, follow these precautions:

- Wear safety gear like glasses, a mask, and gloves to prevent injuries.

- Use an anti-static mat to reduce static electricity buildup, safeguarding the PCB and components.

- Start drilling slowly and maintain a consistent speed for smooth operation.

- Always pay attention to the drill’s direction and distance traveled to avoid damaging components or the board.

- Ensure you use the correct size PCB drill bit to prevent inaccuracies in hole sizes.

- Start drilling from the center of the board to maintain accuracy.

- When working with multi-layered boards, drill through each layer starting from the center.

Essential Tips for Drilling a PCB

Tips and Techniques for Successful PCB Drilling

Here are some valuable tips to guide you through the process of drilling a PCB.

FAQs About PCB Drilling

What Sizes of Holes Should I Drill in a PCB?

The hole size depends on the component being drilled; refer to a size chart for the appropriate drill bit size.

Understanding PCB Drilling Temperature

PCB drilling temperature refers to the spindle temperature of the drilling machine during operation.

Time Required for PCB Drilling

The drilling time varies based on the material and drill machine used, typically ranging from 5 to 15 minutes.

Tools Needed for PCB Drilling

Special tools like drill bits and spindles are essential for PCB drilling, available at hardware stores or from your manufacturer.

Introduction to Drill Press and Its Usage

A drill press is ideal for heavy materials like granite, providing faster and more efficient drilling compared to tabletop machines.

In Conclusion

Drilling a PCB may seem daunting at first, but with practice and attention to detail, it can be done successfully. Remember to drill from the center and ensure correct hole sizes for a safe and effective PCB drilling experience.