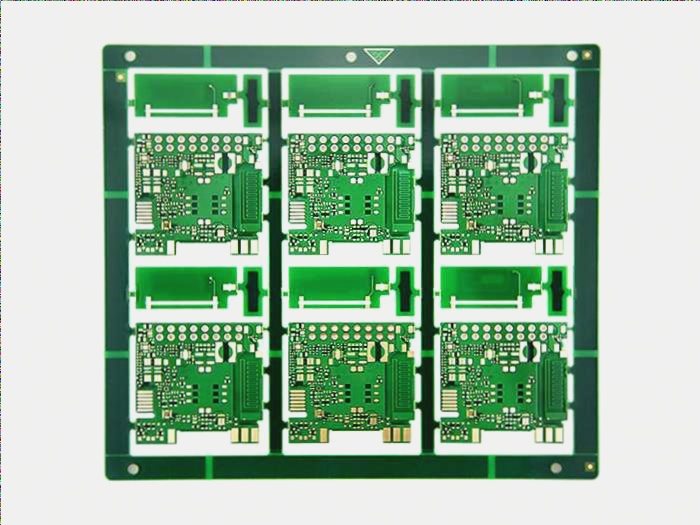

Equipment Types in PCB Production

1. Horizontal vs. Vertical Electroplating Lines

When it comes to producing printed circuit boards, the two main types of electroplating equipment used are horizontal and vertical electroplating lines. The key difference between these two lies in how they transport circuit boards. These differences not only impact the transportation process but also affect maintenance requirements.

2. Daily Maintenance Tips

Maintenance of Tanks

While the transportation methods differ between vertical and horizontal plating lines, the maintenance of tanks remains quite similar. It is essential to clean the pickling tank and replace the bath solution every 7 days. Regular inspections and cleaning of various components within the tanks are necessary to ensure smooth operations.

Vibration Mechanism Care for Vertical Lines

To achieve uniform copper deposition, the vibration mechanism in vertical electroplating lines plays a crucial role. Regular upkeep of this mechanism is vital for quality output.

Crane Maintenance for Vertical Lines

The cranes and hangers used in vertical electroplating lines require weekly cleaning and periodic inspections to ensure proper functioning. Regular maintenance routines help prevent unexpected breakdowns.

Conveying Device Upkeep for Horizontal Lines

Rollers are used in horizontal electroplating lines to move circuit boards through various tanks. Maintenance of these conveying devices is essential to prevent operational issues and maintain product quality.

Circulating Filter System Maintenance

Regular checks and replacements of filter components are necessary to maintain the quality and flow rate of the filtration system. Proper maintenance ensures the effective removal of impurities from the plating process.

General Parts Maintenance

From power supplies to electrical components, regular inspections and replacements are crucial for the overall performance of the electroplating equipment. Ensuring all parts are in top condition helps prevent downtime and improves efficiency.

Pre-Shutdown Maintenance

Maintenance Tips for Long-Term Shutdown of Equipment

- Perform regular maintenance to prevent corrosion and aging.

- Clean and keep the floor dry.

- Ensure machine platform, tanks, drive components, and hangers are clean and dry.

- Protect motors by wrapping them in plastic.

- Grease all bearings to prevent rust.

- Clean pipelines and syrups in the filter barrel.

- Remove and clean the filter element.

- Clean all heaters in the tank to remove dirt and keep them dry.

Maintenance of Electroplating Equipment in PCB Production

Electroplating equipment used in PCB production may vary among processes and manufacturers, resulting in different maintenance requirements. However, regardless of these variations, timely and correct maintenance is essential for optimal performance. Proper maintenance ensures that the equipment operates normally, maintains stable performance, and upholds production output and quality standards.