The Importance of ESD Protection in Electronic Product Design

ESD, or Electro-Static Discharge, is a critical consideration in electronic product design. It involves the generation of static electricity through various means and can lead to product crashes or component damage if not properly addressed.

Understanding ESD Discharge Testing

- Contact discharge and air discharge are two common methods of ESD testing, with test voltages ranging from 2KV to 8KV.

- Market considerations play a crucial role in determining specific testing requirements for different regions.

Effective Strategies for Electrostatic Protection

- Preventing external charges from entering the circuit board is essential to avoid damage.

- Shielding the board from external magnetic fields and mitigating hazards from electrostatic fields are key steps in protection.

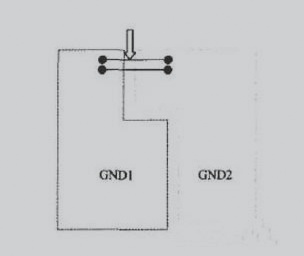

Methods for Electrostatic Protection in Circuit Design

- Avalanche diode clamping quickly dissipates high voltages to protect the circuit board.

- Placing ceramic capacitors in critical positions and minimizing cable length can help reduce damage risks.

- Ferroxide beads effectively attenuate ESD currents and suppress radiation.

- Tip discharge and LC filters offer additional protection against static electricity.

Additional Tips for ESD Prevention

- Utilizing multilayer boards and proper routing techniques can enhance ESD prevention.

- Connecting cables to the housing and using isolation-based protection simplifies circuit design complexity.

- Decoupling capacitors with low ESL and ESR values are crucial for effective ESD protection.

In conclusion, protecting power supplies and signal lines is paramount in preventing ESD current flow into PCBs. Remember, as the saying goes, “a well-grounded board reigns supreme.”