1. A comparison of the hole diameter of the 300um drilled pin hole in a general

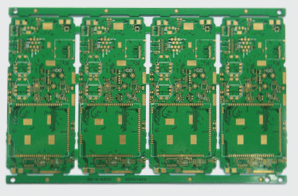

1. PCB build-up circuit boards are primarily completed through chemical processes, with only a small portion involving perforation. The circuit density of these boards is significantly higher than that of traditional FR4 circuit boards, which impacts the quality control inspection methods used. For build-up circuit boards, controlling process errors is crucial. Thus, selecting and managing the process control parameters is essential. Since many process parameters cannot be directly inspected, monitoring them is a key factor in determining the maturity of mass production technology for build-up circuit boards.

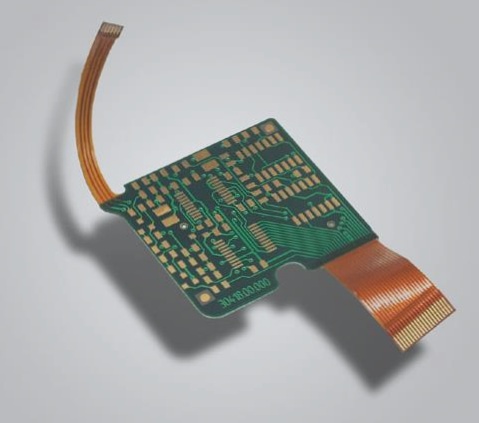

2. Choosing the best process conditions for printed circuit boards is critical. A major issue with build-up printed circuit boards stacked sequentially is that as the number of layers increases, the process yield tends to decrease. The overall yield is calculated by multiplying the yield of each layer. For example, if each layer has a yield of 95%, then the yield for four overlapping layers is only 0.95^4 = 0.81.

3. Therefore, the number of layers in a build-up printed circuit board should be minimized while meeting functional requirements, and the design should maximize the functionality of the FR4 printed circuit board. Various applications can achieve required circuit functions through different combinations of build-up circuit boards and base layers, optimizing size and cost. However, since the 1970s, even FR4 circuit boards have increasingly featured more layers due to higher density requirements, leading to higher costs and limited practical use. In contrast, build-up circuit boards, with their high circuit density per layer, allow for greater increases in overall board density as the number of layers increases.

1. PCB build-up circuit boards are primarily completed through chemical processes, with only a small portion involving perforation. The circuit density of these boards is significantly higher than that of traditional FR4 circuit boards, which impacts the quality control inspection methods used. For build-up circuit boards, controlling process errors is crucial. Thus, selecting and managing the process control parameters is essential. Since many process parameters cannot be directly inspected, monitoring them is a key factor in determining the maturity of mass production technology for build-up circuit boards.

2. Choosing the best process conditions for printed circuit boards is critical. A major issue with build-up printed circuit boards stacked sequentially is that as the number of layers increases, the process yield tends to decrease. The overall yield is calculated by multiplying the yield of each layer. For example, if each layer has a yield of 95%, then the yield for four overlapping layers is only 0.95^4 = 0.81.

3. Therefore, the number of layers in a build-up printed circuit board should be minimized while meeting functional requirements, and the design should maximize the functionality of the FR4 printed circuit board. Various applications can achieve required circuit functions through different combinations of build-up circuit boards and base layers, optimizing size and cost. However, since the 1970s, even FR4 circuit boards have increasingly featured more layers due to higher density requirements, leading to higher costs and limited practical use. In contrast, build-up circuit boards, with their high circuit density per layer, allow for greater increases in overall board density as the number of layers increases.