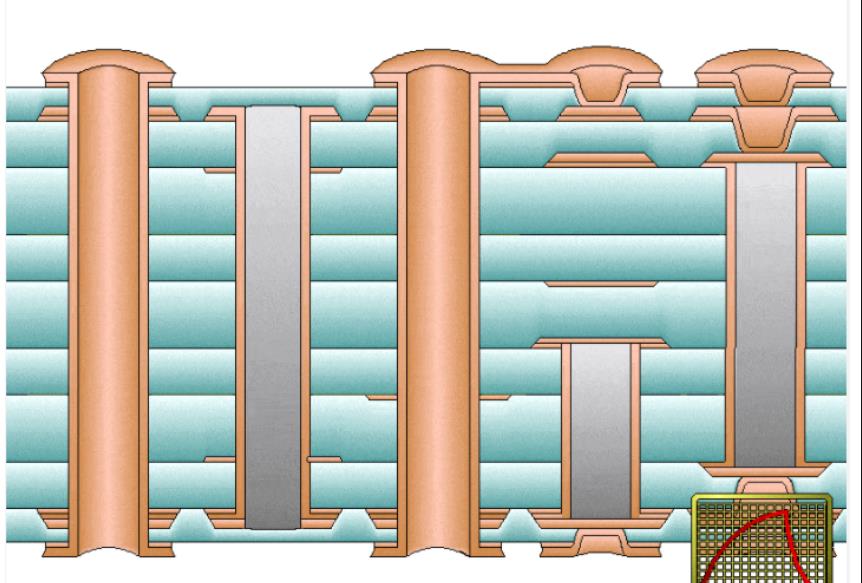

One of the often overlooked aspects of PCB design is the holes for mounting components. It is crucial to specify the tolerance of hole size in PCB manufacturing in order to ensure the correct fit of plated through hole (PTH) components.

Altium Designer PCB design software offers the capability to add hole tolerance attributes for pads and through holes, which can then be communicated to the manufacturer by including them in the drill table. Here are five tips to efficiently specify the hole size in your next PCB design:

1. PCB Tolerance

Refer to the component data book for the plus/minus tolerances to accommodate changes in aging, wear, temperature, plating, materials, and processing. For example, a 1/4 watt resistor manufacturer’s data sheet specifies a wire diameter of 0.022 ± 0.003. This means the actual diameter can vary from 0.019 to 0.025.

2. Hole Tolerance

Typically, the PCB manufacturer specifies a hole tolerance of ± 0.004. Regardless of whether the tolerance is at the upper or lower limit, the wire must always fit into the hole. Therefore, the minimum hole size must accommodate the maximum resistance lead plus tolerance (0.022 resistance lead + 0.003 resistance lead tolerance), plus 0.004 PCB hole tolerance. This results in a minimum allowable hole size of 0.029 inch on the plate.

3. Factors Affecting Hole Size

During drilling, bit wear can cause the hole to become smaller. Additionally, drill bit vibrations or slight shaking can result in a slightly larger hole. Subsequently, the holes are plated, and the plating thickness can vary between batches or locations on the plate. Thermal expansion or contraction of the PCB substrate during processing should also be taken into consideration.

Therefore, the hole tolerance is critical in the design process to ensure the correct placement of PTH parts. As a rule of thumb, you should make PCB holes 0.007 inches larger than the part wire diameter to accommodate all tolerances, drill wear or wobble, and plating changes. There is no default hole tolerance in Altium Designer. You can adjust hole tolerance attributes in the Pads and Attributes dialog box. Hole tolerances and default values can also be established in the Pad Via Library panel and Footprint Library.

5 Tips for Specifying PCB Hole Tolerance

The hole tolerance in Altium Designer can be accessed and edited in several different ways, which we will study below. In each method, you can set the minimum (-) and maximum (+) hole tolerance attributes.

You can quickly set pad/through-hole tolerances based on individual attributes.

1. Right click a pad or through hole and select Properties. In the Pad Properties dialog box (Figure 1), edit the hole tolerance at Hole Information.

2. In the Through Hole Properties dialog box, edit the hole tolerance at Tolerance in the upper left corner of Figure 2.

You can also specify hole tolerances using pads or through hole templates.

3. Right click Pad Via Library and select Add Through Hole Template or Add Pad Template. The hole tolerance can be set at Hole Information.

Conveniently, you can set the hole tolerance of multiple pads or through holes at the same time.

4. Open the PCB Inspector panel, as shown in Figure 3. Select the pad or through hole on the PCB you want to set, and enter the required hole metric value in the right column under the Object Specific panel.

Hole tolerance bars can also be added and edited from the PCB panel using the Hole Size Editor. Right click Columns>Hole Tolerance (+) and Hole Tolerance (-) under the Unique Holes heading. You can change the tolerance attributes by clicking in the Hole Tolerance column.

You can add hole tolerances for multiple stitched through holes to save time.

5. Click “Tools”>”Via Stitting/Shielding”>”Add Stitting to Net”. Add hole tolerance information at Tolerance under the Via Style section.

You can view the tolerances in the drilling table in two ways: one or two columns to display the tolerance attributes.

In the Drill Table Properties dialog box, click Add Column. Select Hole Tolerance to view all the tolerance attributes in a column, and select Hole Tolerance. This column displays the minimum and maximum properties. Alternatively, you can choose to display the Min and Max setup hole tolerance attributes in separate columns. For the latter selection, select Hole Tolerance (+) and Hole Tolerance (-). Of course, you can also choose to display only the minimum or maximum set hole tolerances.

Table 1 Example table showing all hole tolerance columns

You can also group them by hole tolerance. From the Drill Symbols dialog box (click Configure Drill Symbols in the Drill Table dialog box), click Grouping, and then select Hole Tolerance.

Note that when hole tolerance information is added to pads and through holes, unless all pads or through holes grouped under the “Count column” column have the same hole tolerance attribute, the hole tolerance value will be displayed as * (asterisk).

Note: After adding information to the drill table, you must click OK to exit the Drill Table dialog box, or your changes will not be saved.

Conclusion

Ensuring proper hole tolerance is critical for the PTH components to be correctly installed on the PCB design. Altium Designer simplifies the documentation of your hole size tolerances so that your tolerance specifications can be easily communicated to your manufacturers.

Altium Designer PCB design software offers the capability to add hole tolerance attributes for pads and through holes, which can then be communicated to the manufacturer by including them in the drill table. Here are five tips to efficiently specify the hole size in your next PCB design:

1. PCB Tolerance

Refer to the component data book for the plus/minus tolerances to accommodate changes in aging, wear, temperature, plating, materials, and processing. For example, a 1/4 watt resistor manufacturer’s data sheet specifies a wire diameter of 0.022 ± 0.003. This means the actual diameter can vary from 0.019 to 0.025.

2. Hole Tolerance

Typically, the PCB manufacturer specifies a hole tolerance of ± 0.004. Regardless of whether the tolerance is at the upper or lower limit, the wire must always fit into the hole. Therefore, the minimum hole size must accommodate the maximum resistance lead plus tolerance (0.022 resistance lead + 0.003 resistance lead tolerance), plus 0.004 PCB hole tolerance. This results in a minimum allowable hole size of 0.029 inch on the plate.

3. Factors Affecting Hole Size

During drilling, bit wear can cause the hole to become smaller. Additionally, drill bit vibrations or slight shaking can result in a slightly larger hole. Subsequently, the holes are plated, and the plating thickness can vary between batches or locations on the plate. Thermal expansion or contraction of the PCB substrate during processing should also be taken into consideration.

Therefore, the hole tolerance is critical in the design process to ensure the correct placement of PTH parts. As a rule of thumb, you should make PCB holes 0.007 inches larger than the part wire diameter to accommodate all tolerances, drill wear or wobble, and plating changes. There is no default hole tolerance in Altium Designer. You can adjust hole tolerance attributes in the Pads and Attributes dialog box. Hole tolerances and default values can also be established in the Pad Via Library panel and Footprint Library.

5 Tips for Specifying PCB Hole Tolerance

The hole tolerance in Altium Designer can be accessed and edited in several different ways, which we will study below. In each method, you can set the minimum (-) and maximum (+) hole tolerance attributes.

You can quickly set pad/through-hole tolerances based on individual attributes.

1. Right click a pad or through hole and select Properties. In the Pad Properties dialog box (Figure 1), edit the hole tolerance at Hole Information.

2. In the Through Hole Properties dialog box, edit the hole tolerance at Tolerance in the upper left corner of Figure 2.

You can also specify hole tolerances using pads or through hole templates.

3. Right click Pad Via Library and select Add Through Hole Template or Add Pad Template. The hole tolerance can be set at Hole Information.

Conveniently, you can set the hole tolerance of multiple pads or through holes at the same time.

4. Open the PCB Inspector panel, as shown in Figure 3. Select the pad or through hole on the PCB you want to set, and enter the required hole metric value in the right column under the Object Specific panel.

Hole tolerance bars can also be added and edited from the PCB panel using the Hole Size Editor. Right click Columns>Hole Tolerance (+) and Hole Tolerance (-) under the Unique Holes heading. You can change the tolerance attributes by clicking in the Hole Tolerance column.

You can add hole tolerances for multiple stitched through holes to save time.

5. Click “Tools”>”Via Stitting/Shielding”>”Add Stitting to Net”. Add hole tolerance information at Tolerance under the Via Style section.

You can view the tolerances in the drilling table in two ways: one or two columns to display the tolerance attributes.

In the Drill Table Properties dialog box, click Add Column. Select Hole Tolerance to view all the tolerance attributes in a column, and select Hole Tolerance. This column displays the minimum and maximum properties. Alternatively, you can choose to display the Min and Max setup hole tolerance attributes in separate columns. For the latter selection, select Hole Tolerance (+) and Hole Tolerance (-). Of course, you can also choose to display only the minimum or maximum set hole tolerances.

Table 1 Example table showing all hole tolerance columns

You can also group them by hole tolerance. From the Drill Symbols dialog box (click Configure Drill Symbols in the Drill Table dialog box), click Grouping, and then select Hole Tolerance.

Note that when hole tolerance information is added to pads and through holes, unless all pads or through holes grouped under the “Count column” column have the same hole tolerance attribute, the hole tolerance value will be displayed as * (asterisk).

Note: After adding information to the drill table, you must click OK to exit the Drill Table dialog box, or your changes will not be saved.

Conclusion

Ensuring proper hole tolerance is critical for the PTH components to be correctly installed on the PCB design. Altium Designer simplifies the documentation of your hole size tolerances so that your tolerance specifications can be easily communicated to your manufacturers.