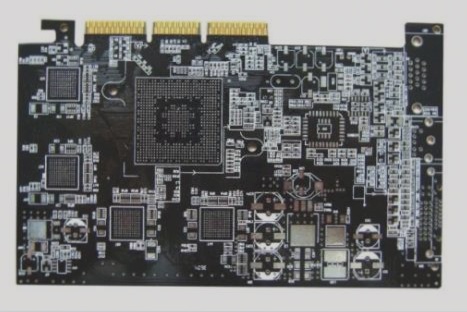

Latest Trends in PCB Technology

With the continuous evolution of technology, the printed circuit board (PCB) market is constantly adapting to meet the demands of consumers and emerging trends. Here are four significant technology trends shaping the future of PCBs:

- Miniaturization: The trend towards smaller and more compact electronic devices is driving innovation in PCB manufacturing. High-density interconnection (HDI) technology is crucial in achieving miniaturization and enhancing the efficiency of electronic products across various industries.

- Sustainability: In response to environmental concerns, the PCB industry is shifting towards sustainable practices. This includes the transition to lead-free solder and exploring alternative materials like resin-coated copper and liquid crystal polymers for improved performance and eco-friendliness.

- Wearable Technology: The rise of wearable devices is influencing PCB design and functionality. PCBs play a vital role in enabling modern healthcare technologies, such as secure data storage and camera integration for medical procedures.

- Integration of Consumer Technologies: PCBs are at the forefront of integrating new consumer technologies, from compact dashboard cameras to connected hubs that sync with smartphones. These advancements cater to evolving consumer preferences and enhance public oversight capabilities.

As the PCB industry continues to evolve, opportunities for innovation and growth abound. Stay tuned for the latest developments driving the future of PCB technology.