Effective Ways to Cut and Split PCBs

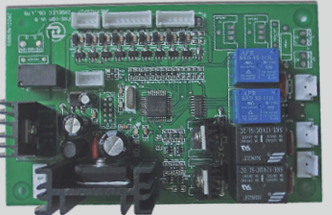

- When it comes to cutting and splitting PCBs, manual methods, knife splitting, and punch processing are commonly used techniques.

- Traditional approaches to PCB processing may result in issues like damage, deformation, burrs, and dust accumulation, which can impact the soldering process.

Latest Innovations in PCB Processing

- Recent advancements in PCB processing include the introduction of PCB laser cutting and splitting machines, offering a non-contact processing solution that eliminates problems like burrs, damage, and deformation.

- Despite the benefits, the high cost associated with PCB laser cutting machines has posed a challenge for many manufacturers looking to adopt this technology.

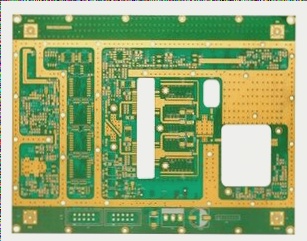

Key Factors Influencing the Cost of Laser Processing Equipment

- Laser Technology: The type of laser used is crucial, with imported lasers such as IPG, SP, AOW, and PI known for their superior stability, especially when working with different PCB substrate materials.

- Cutting Head Selection: Choosing the right cutting head is essential for efficient and precise cutting, with top imported brands like CTI, SCANLAB, and RAYLASE offering high-speed performance.

- Linear Motor Quality: Precision within 3 microns is achieved with high-quality linear motors, particularly those imported from Taiwan, which are essential for handling various processing formats.

- Advanced Control Software: A top-notch control system is critical for the overall performance of the equipment, ensuring seamless integration with hardware and supporting all necessary functions and interfaces.

- Additional Components: Industrial control machines, dust extraction systems, coolers, and stable platforms are among the essential supplementary devices required for optimal laser processing.

Overview of PCB Laser Cutting Machines

When considering the cost of PCB laser cutting machines, it’s important to note that core components like the laser, linear motor, galvanometer, and software system contribute significantly to over 90% of the total equipment cost. These machines are predominantly utilized in industries that demand precise processing, including automotive electronics, consumer electronics, and mobile phone manufacturing.