Important Design Parameters for PCB Layout

-

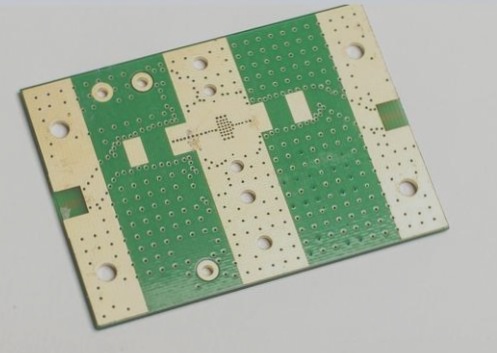

Vias (Conductive Holes)

- Minimum Aperture: 0.3mm (12mil)

- Minimum VIA Hole Diameter: 0.3mm (12mil)

- Via Hole to Hole Spacing: ≥6mil

- Pad to Outline Spacing: 0.508mm (20mil)

-

Line Design

- Minimum Line Spacing: 6mil (0.153mm)

- Minimum Line Width: 6mil (0.153mm)

- Line to Outline Line Spacing: 0.508mm (20mil)

-

PAD Pad (Plug-in Hole)

- Outer Ring of Plug-in Hole: ≥0.2mm (8mil)

- Plug-in Hole to Hole Spacing: ≥0.3mm

- Size of Plug-in Hole: Must be larger than component pins

- Pad to Outline Spacing: 0.508mm (20mil)

-

Solder Mask

- SMD Window Size: ≥0.1mm (4mil)

-

Character Design

The character width should be ≥0.153mm (6mil) and the height should be ≥0.811mm (32mil). The ideal ratio between width and height is 5.

-

Non-Metallized Slot Holes

Minimum Spacing of Slot Holes: ≥1.6mm

-

Imposition

- Imposition Gap for Gap Imposition: ≥1.6mm

- Gapless Imposition Gap: ~0.5mm

- Process Edge: ≥5mm

Latest Information: When designing PCB layouts, it is crucial to consider the size and spacing of vias, lines, pads, solder masks, characters, slot holes, and imposition to ensure smooth production and high-quality results. Keeping these design parameters in mind will help in creating efficient and reliable printed circuit boards.