Crests

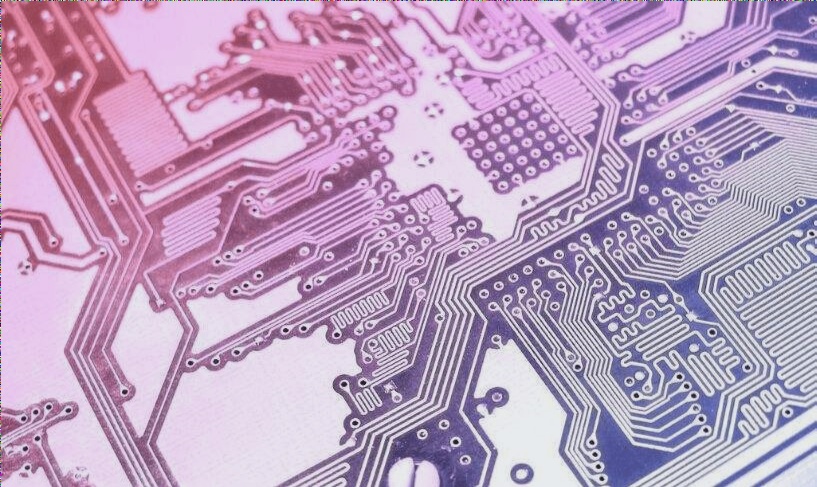

In the wave soldering process, the main focus is on the wave itself. Preheated metal coated with flux and free from contaminants is transported on a conveyor belt to a soldering station. Here, it comes into contact with solder at a specific temperature, leading to a chemical reaction with the flux and interconnection of the solder alloy through the power of the wave. This step is crucial for achieving good welding characteristics. The symmetrical crest, known as the main crest, is commonly used, with parameters such as pump speed, crest height, wetting depth, conveying angle, and conveying speed set to create optimal conditions. Proper adjustments should be made to slow down the solder flow just after it leaves the wave and then gradually stop it. The PCB pushes the solder towards the outlet as the wave progresses. Surface tension and optimized board operation ensure minimal relative motion between components and the wave at the outlet, facilitating solder removal from the board. Adequate inclination is essential to prevent defects like bridging, burrs, wire drawing, and solder balls. Sometimes, hot air flow is necessary at the crest outlet to prevent potential bridging.

After mounting surface mount components on the board’s underside, turbulent chip crests may be used before wave leveling to compensate for air bubbles in the flux or harsh crest areas. The high vertical velocity of the turbulent wave crest helps ensure solder-lead or pad contact. The vibrating section behind the flattened laminar wave can eliminate air bubbles, ensuring satisfactory solder contact. The soldering station should use high-purity solder, maintain a peak temperature of 230-250°C, ensure a total contact time with the wave peak of 3-5 seconds, and immerse the printed board in the wave peak depth of 50-80% to achieve parallel conveying tracks and appropriate flux content in the tin pot.

Cooling After Wave Soldering

A cooling station is typically added at the end of the wave soldering machine to prevent the formation of copper-tin intermetallics in solder joints and expedite assembly cooling to prevent board displacement before the solder solidifies completely. Quick cooling of components helps limit exposure to high temperatures, but aggressive cooling systems should be used cautiously to avoid thermal shock to components and solder joints. A well-controlled forced air cooling system can effectively cool components without causing damage. This system allows for quick handling of boards and keeps components cooler than the cleaning solution, preventing flux residue blistering and unwashable residues caused by reactions with flux dross.

It’s crucial to understand every step of the process to ensure the best welding quality and meet user requirements. Each stage of the SMT assembly process is interconnected, and problems at any point can impact overall reliability and quality. Strict control over parameters such as time/temperature, solder volume, flux composition, and transfer speed is essential. Identifying and addressing welding defects promptly is vital to maintain product quality and technical specifications.