Sure, here are the revisions for the provided text:

1. Standing in the 21st century without knowing about PCBs is nearly impossible. In our technology-oriented world, PCBs have been a game-changer for several years. Hence, it’s not surprising to learn about the PCB fabrication procedure.

2. This guide will assist you in exploring the entire PCB fabrication process and its implications. So, if you want to know more, keep reading.

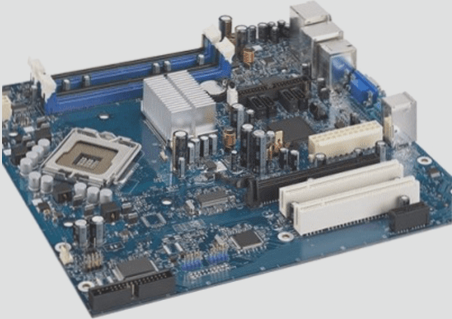

3. Being an inevitable part of every electronic gadget, the PCB fabrication process requires prominence and deep knowledge. There are mainly three types of PCBs available in the market: Single, Double, and Multi-layered. The fabrication process for each is quite similar.

4. From creating the board’s layout to graphic plating, from etching to drying, from drilling to silk-screening, every step of PCB fabrication requires meticulous attention. Precise fabrication is crucial to ensure the proper functioning of electronic devices.

5. Fabrication is a critical aspect of any printed circuit board, involving steps like PCB designing, laminating, drying, etching, and more. Before diving into fabrication, it’s essential to thoroughly understand these related concepts.

6. **PCB Layout Design:** This initial step involves transforming the PCB layout into an output layout. Formulating, manufacturing, and analyzing are the three cycles of this process. While straightforward for simple designs, complex designs may require iterative processes for optimal results.

7. **PCB Manufacturing:** This second step brings the concept to reality. As the name suggests, it involves manufacturing the printed circuit board, comprising two key stages: PCB fabrication, where the circuit board is formed, and PCB assembly (PCBA), where components are mounted.

8. **PCB Inspection:** Once previous steps are completed, it’s crucial to analyze and finalize the PCB’s performance. This step is non-negotiable, determining whether the design meets goals or needs adjustments.

9. **PCBA:** PCB assembly is the final step in the fabrication process. Here, components are soldered onto the board to complete the assembly.

10. In summary, these steps outline the comprehensive process of PCB fabrication.

11. Printed circuit board fabrication involves various operations and specialized techniques:

12. **PCB Designing:** Solid planning and layout are essential prerequisites for successful PCB fabrication. A blueprint helps designers determine paths, component placements, dimensions, etc.

13. **Production Preparation:** This involves several steps, starting with cutting laminates to panel size, followed by drying to eliminate moisture. Additional steps include internal layer drying, inner film application, and exposure.

14. **Inner Layer Etching:** Etching is crucial for preserving copper in inner layers. Once etched, the film is developed.

15. **AOI of Inner Layer:** Automatic Optical Inspection (AOI) verifies the cleanliness of etching and checks for potential short circuits.

16. **Lamination:** Following inner layer inspection, lamination occurs.

17. **Drilling:** After lamination, holes are drilled.

18. **Electroless Copper Deposition:** A light copper coating repairs drilled holes, typically around 2-3 um thick.

19. **Horizontal Electrolytic Plating:** This step solidifies the thin hole layer with an 8-9 um thick copper layer.

20. **Outer Layer Imaging:** Similar to inner layer processes, the outer layer is exposed, developed, and imaged.

21. **Graphic Plating:** Mainly involving copper and tin plating, this step concludes with film removal.

22. **Outer Layer Etching:** Here, the outer layer is etched, removing tin.

23. **Solder Mask Application:** Once etching is complete, the entire panel is coated with liquid solder mask.

24. **Silkscreen Printing:** Essential data is printed on the board during this step.

25. **Surface Finish:** Ensures PCB durability and performance.

26. **Electrical Testing:** Crucial to verify PCB functionality.

27. **Packaging and Delivery:** Final products are packaged and prepared for sale.

28. In essence, understanding PCB fabrication is crucial for making informed decisions regarding materials, layouts, limitations, and paths during the process.

29. Lastly, PCB fabrication is intricate and demands precise knowledge and expertise. If issues arise, it’s advisable to consult skilled PCB manufacturers for optimal results.

These edits aim to clarify and refine the original text, maintaining its informational value and readability.