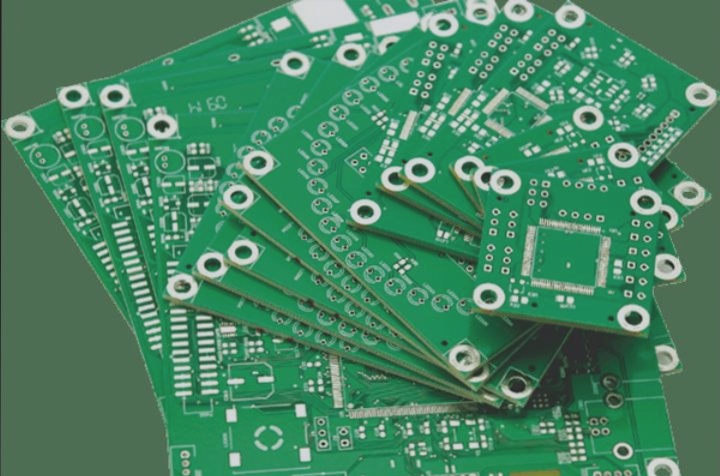

The Advanced PCB Manufacturing Process: A Detailed Overview

The process of PCB manufacturing at circuit board prototyping companies involves a sophisticated series of steps, starting from initial preparation and concluding with final packaging and storage. This intricate process includes cutting sheet materials and advancing to PCB board production, encompassing various crucial stages.

Key Steps in PCB Manufacturing:

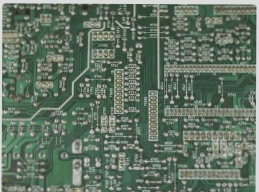

- Opening and Inner Layer Production: The process begins with opening and inner layer production, setting the foundation for subsequent stages.

- Lamination: Utilizing a lamination process, separate layers are created, ensuring the integrity of the PCB.

- Drilling: Small diameter tungsten carbide drill bits are used to create holes in the PCB, crucial for component placement and connectivity.

- Copper Immersion and Electroplating: Electroplating with solder provides a durable surface for etching, enhancing the PCB’s functionality.

- Outer Layer Production: Following electroplating, outer layer production is conducted to finalize the PCB structure.

- Inspection and Testing: Rigorous inspection and testing processes are implemented to ensure quality and functionality.

- Solder Mask Application: Solder mask application is carried out to protect non-soldered areas, crucial for preventing short circuits.

- Component Assembly: Components are meticulously assembled on the PCB to create a functional printed circuit assembly.

- Surface Treatment: Surface treatment processes are applied to enhance the PCB’s performance and longevity.

- Final Packaging and Storage: The PCB undergoes final inspection before being packaged and stored, ready for distribution.

Embracing Innovation for Safety and Quality

The PCB manufacturing landscape is evolving, with a focus on minimizing risks to production workers and enhancing product quality. Manufacturers are adopting safer chemical processes and reducing the use of substances like lead, driven by health and environmental concerns. Recent publications emphasize the importance of sustainable practices and highlight the role of NGOs in promoting responsible manufacturing.

WellCircuits Limited: Your Trusted PCB Partner

Specializing in high-precision circuit boards, WellCircuits Limited offers a diverse range of products, including HDI, thick copper, backplanes, rigid-flex, and buried capacitance boards. Their expertise extends to double-sided, multi-layer, and impedance-controlled PCBs, catering to the unique requirements of their customers. With a commitment to quality and innovation, WellCircuits Limited is your go-to partner for cutting-edge PCB solutions.