Mark Points in PCB Design

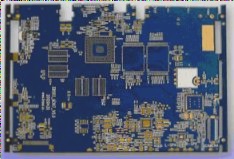

A mark point is a crucial reference used in PCB designs, especially in surface mount technology (SMT) assembly. These points act as alignment markers on the PCB, enabling automatic placement machines to accurately position components during manufacturing. Mark points can be made of bare copper or copper protected with a transparent anti-oxidation coating to maintain their integrity.

The Role of Mark Points in PCB Design and Manufacturing

Mark points are essential for precise component placement in the SMT process. They aid in accurate positioning and calibration of placement machines, directly impacting the efficiency and accuracy of automated assembly processes. There are three main types of mark points:

- Single-board Mark Points: Used to define the position of all circuit features on the PCB, ensuring correct component placement.

- Jigsaw Mark Points: Assist in positioning circuit features on multi-board setups or complex designs.

- Local Mark Points: Designed for fine, component-specific alignment, crucial for components like QFP, CSP, and BGA.

Function of Mark Points in SMT

Mark points in SMT are vital for the placement machine to identify and position components accurately. These marks are used by the machine’s optical system to locate and calibrate the placement tool, ensuring precise component mounting on the PCB.

Impact on SMT Efficiency

Correct selection and placement of mark points directly impact the efficiency of the placement machine. Misaligned or hard-to-detect mark points can lead to errors in component placement, affecting production speeds and quality.

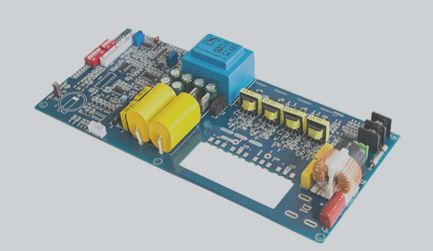

PCB Surface Treatment and Tin Spraying

In addition to mark points, surface treatment processes like tin spraying (HAL) play a crucial role in PCB manufacturing. Tin spraying enhances pad conductivity, improves solderability, prevents oxidation, and ensures strong electrical connections for long-term PCB performance.

Key Points in PCB Assembly Precision

Mark points are crucial for PCB assembly precision, guiding automated machines for correct alignment. The selection of these points and effective surface treatments like tin spraying ensure high-quality PCB manufacturing processes.

SMOBC and HAL Surface Coatings for PCBs

SMOBC (Solder Mask Over Bare Copper) and HAL (Hot Air Leveling) are common surface treatments for PCBs, ensuring reliability and performance. The quality of tin spraying in the HAL process directly impacts solderability and assembly quality, becoming a critical point for quality control.

Differences Between Leaded and Lead-Free Tin Spraying

- Lead Content: Lead-free tin contains a maximum of 0.5% lead, while leaded tin can have up to 37% lead content.

- Surface Appearance: Leaded tin results in a shinier surface, while lead-free tin like SAC tends to have a duller appearance.

- Wettability: Leaded tin provides superior wettability compared to lead-free tin (SAC), resulting in more efficient soldering.

- Soldering Characteristics: Lead enhances soldering by lowering the melting point and improving flow, making it easier to work with.

- Temperature and Melting Point: Leaded tin has a lower melting point and better mechanical strength compared to lead-free tin.

- Environmental Considerations: Lead-free tin is environmentally friendly and RoHS compliant, while leaded tin contains toxic lead.

- Leaded Tin’s Environmental Impact: Leaded tin does not meet modern environmental standards due to its lead content.

Conclusion

Both leaded and lead-free tin spraying processes are crucial for high-quality PCB production, each with unique advantages. Lead-free tin offers a safer, environmentally friendly solution with stronger joints, while leaded tin is easier to work with but poses health risks. The choice depends on regulatory requirements, cost, and performance specifications, with quality control in tin spraying being paramount for reliable PCBs.