The PCB design of a rigid-flex board can seem complex, requiring careful consideration of signal routing and power distribution. Interference and heat issues are often encountered along the way. However, the overall approach is quite clear and can be distilled into two main aspects: “how to position components” and “how to make connections.”

1. Follow the layout principle of “big first, then small, difficult first, then easy,” meaning that the most important circuit units and core components should be placed first. This is similar to a buffet: with limited appetite, you choose the items you like most first. Similarly, when PCB space is limited, prioritize the most critical components.

2. The layout should follow the principle block diagram, and the main components should be positioned based on the primary signal flow of the board. The layout should meet the following requirements as closely as possible: keep the overall wiring as short as possible, with the key signal traces being the shortest; place decoupling capacitors as close as possible to the IC’s power supply pins, and minimize the loop between the capacitor, power supply, and ground; reduce unnecessary signal paths to prevent potential issues during operation.

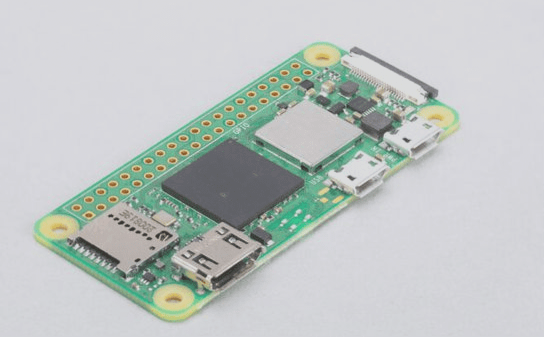

3. The arrangement of components should facilitate both debugging and maintenance. Large components should not be placed near smaller ones, and there should be ample space around components that require frequent debugging. A cramped layout can lead to significant difficulties during maintenance.

4. For circuit sections with similar structures, use a “symmetrical” layout as much as possible. Optimize the layout by adhering to standards such as uniform distribution, a balanced center of gravity, and an aesthetically pleasing arrangement. Baineng.com, a subsidiary of Qinji Group, is a leading electronic industry service platform in China, offering solutions like online component sourcing, sensor procurement, PCB customization, BOM management, material selection, and more. It provides comprehensive, one-stop services to meet the needs of small and medium-sized customers in the electronics industry.

5. Components of the same type, such as through-hole parts, should be aligned in the same direction, either along the X or Y axis. Likewise, polarized discrete components should be consistently oriented in one direction (X or Y) to simplify production and inspection.

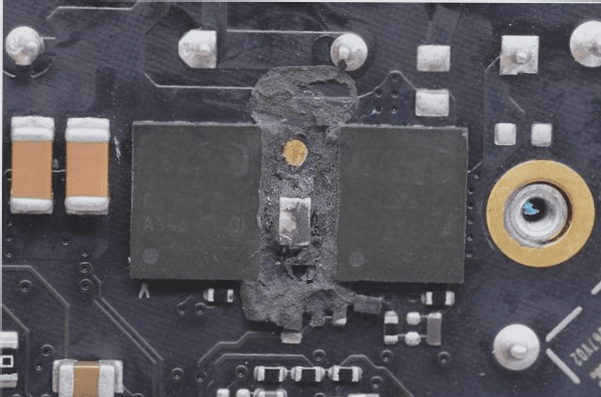

6. Heating components should be evenly distributed across the PCB to ensure effective heat dissipation throughout the board and the entire system. Temperature-sensitive components, excluding those specifically designed for temperature detection, should be placed away from heat-generating parts.

7. High-voltage and high-current signals must be fully separated from low-voltage, low-current signals. Analog signals should be isolated from digital ones, and high-frequency signals should be kept separate from low-frequency signals. Ensure adequate spacing for high-frequency components. When laying out components, it is beneficial to place components that share the same power supply close together to simplify future power supply separation.

The considerations above pertain to the “how to place” aspect of layout. The “how to connect” part is more complex. Generally, the following principles apply:

– Priority of key signal lines: High-priority routing should be given to critical signals such as analog small signals, high-speed signals, clock signals, and synchronization signals.

– Density priority principle: Begin routing from the most complex devices on the PCB, starting with the densest areas of the board to streamline the wiring process.

1. Follow the layout principle of “big first, then small, difficult first, then easy,” meaning that the most important circuit units and core components should be placed first. This is similar to a buffet: with limited appetite, you choose the items you like most first. Similarly, when PCB space is limited, prioritize the most critical components.

2. The layout should follow the principle block diagram, and the main components should be positioned based on the primary signal flow of the board. The layout should meet the following requirements as closely as possible: keep the overall wiring as short as possible, with the key signal traces being the shortest; place decoupling capacitors as close as possible to the IC’s power supply pins, and minimize the loop between the capacitor, power supply, and ground; reduce unnecessary signal paths to prevent potential issues during operation.

3. The arrangement of components should facilitate both debugging and maintenance. Large components should not be placed near smaller ones, and there should be ample space around components that require frequent debugging. A cramped layout can lead to significant difficulties during maintenance.

4. For circuit sections with similar structures, use a “symmetrical” layout as much as possible. Optimize the layout by adhering to standards such as uniform distribution, a balanced center of gravity, and an aesthetically pleasing arrangement. Baineng.com, a subsidiary of Qinji Group, is a leading electronic industry service platform in China, offering solutions like online component sourcing, sensor procurement, PCB customization, BOM management, material selection, and more. It provides comprehensive, one-stop services to meet the needs of small and medium-sized customers in the electronics industry.

5. Components of the same type, such as through-hole parts, should be aligned in the same direction, either along the X or Y axis. Likewise, polarized discrete components should be consistently oriented in one direction (X or Y) to simplify production and inspection.

6. Heating components should be evenly distributed across the PCB to ensure effective heat dissipation throughout the board and the entire system. Temperature-sensitive components, excluding those specifically designed for temperature detection, should be placed away from heat-generating parts.

7. High-voltage and high-current signals must be fully separated from low-voltage, low-current signals. Analog signals should be isolated from digital ones, and high-frequency signals should be kept separate from low-frequency signals. Ensure adequate spacing for high-frequency components. When laying out components, it is beneficial to place components that share the same power supply close together to simplify future power supply separation.

The considerations above pertain to the “how to place” aspect of layout. The “how to connect” part is more complex. Generally, the following principles apply:

– Priority of key signal lines: High-priority routing should be given to critical signals such as analog small signals, high-speed signals, clock signals, and synchronization signals.

– Density priority principle: Begin routing from the most complex devices on the PCB, starting with the densest areas of the board to streamline the wiring process.