Electroplating PCB Industry Insights

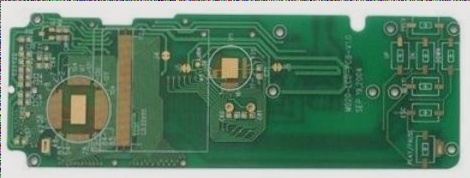

The Growing Importance of Electroplating in PCB Manufacturing

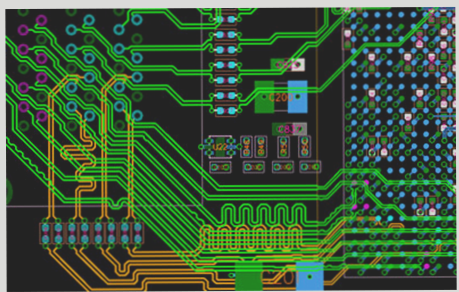

The global electroplating PCB industry is rapidly expanding and plays a significant role in the electronic component sector. With electronic products becoming smaller and more intricate, the demand for denser interconnections is on the rise. This shift has led to the development of innovative solutions such as electroplating hole filling processes.

Advantages of Electroplating Hole Filling

- Facilitates stacked holes and via-on-pad configurations

- Enhances electrical performance for high-frequency designs

- Aids in efficient heat dissipation

- Completes hole filling and electrical interconnection simultaneously

- Provides higher reliability and conductivity compared to adhesives

Key Factors to Consider in Electroplating Processes

- Anode Type: Soluble anodes like phosphorous copper balls vs. insoluble anodes made from titanium mesh coated with mixed oxides of tantalum and zirconium.

- Cathode-Anode Distance: Crucial spacing complying with Faraday’s first law.

- Stirring Methods: Mechanical, electric, air shaking, jet stirring, and considerations for jet design.

- Current Density and Temperature: Impact on copper deposition rate and hole filling efficiency.

Exploring these factors in electroplating PCB processes is essential for achieving optimal results and ensuring the reliability and performance of electronic components.

Rectifier in Electroplating Process

- The rectifier is crucial for electroplating, especially in patterned hole filling.

- Output accuracy of the rectifier is vital, with higher precision needed for finer lines and smaller holes.

- Positioning the rectifier close to the plating tank is recommended to minimize cable length and improve performance.

- For plating tanks with groove width over 1.6m, a double-sided power supply method is suggested for even current distribution.

Waveform Options in Electroplating

- Two main methods are pulse electroplating and DC electroplating, each with its advantages.

- Pulse electroplating with a PPR rectifier offers better performance for thicker boards.

- DC electroplating, while easier to operate, may not be sufficient for thicker boards.

Influence of Substrate Material

- Substrate material significantly affects hole filling, considering factors like dielectric material and hole shape.

- Different materials impact hole filling differently, with non-glass fiber materials filling holes more easily.

- Aspect ratio plays a crucial role in hole filling technology, especially for smaller holes.

- Uniformity and thickness of the electroless copper plating layer are essential for optimal hole filling performance.

If you require PCB manufacturing services, feel free to contact us.