Global Vision Technology Quality Management Process

Global Vision Technology is committed to continuous improvement through PDCA management principles. Guided by the ISO9001 standard, we refine internal processes, elevate supply chain management, and provide top-tier product manufacturing services. Our stringent oversight covers process design, NPI product introduction, DFM inspection, PCBA manufacturing, quality control testing, and personnel training to establish a robust quality management system.

DFM Inspection Checklist

- Verify file version and last update time

- Determine leaded/lead-free process

- Ensure clear component numbers and silkscreen

- Validate BOM details with manufacturer’s brand, part number, description, and tag number

- Confirm PCB production specifics: material, thickness, copper thickness, layers, surface treatment, character color, and special processes

- Review PCB layering and boarding method

- Provide correct SMT patch file

- Execute program burning and function test plan

- Verify completeness of finished product assembly manual and schematic diagram

- Address any other special process requirements

New Product Introduction Meeting Protocol

Our comprehensive new product introduction meetings involve personnel from various departments to ensure a smooth transition. Key agenda items include:

- Client project background and special requirements

- Internal customer and product number assignment

- Production, purchase, and delivery quantity clarification

- Project process evaluation and quality control points identification

- PCB and electronic components procurement cycle clarification

- Draft production plan proposal

- Jigs, fixtures, and auxiliary materials preparation

- Customer product test plan clarification

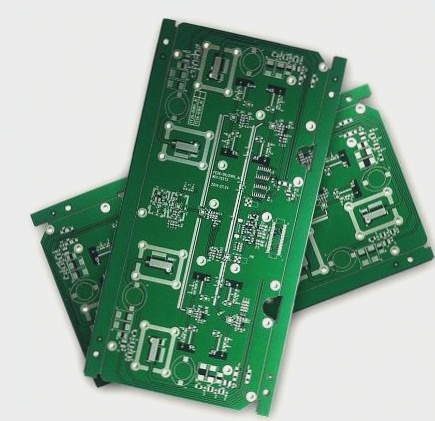

PCB Manufacturing Excellence

At Global Vision Technology, we ensure top-notch PCB manufacturing by focusing on key quality control points:

- Selection of high-quality brand plates

- Partnership with top circuit board suppliers

- Continuous supplier relationship management

- Expertise in 3mil line width, multi-layer, HDI, impedance, and blind buried vias

- Mandatory 100% electrical testing for all delivered PCBs

Electronic Components Procurement Strategy

- 100% adherence to customer-specified brand and material numbers in the BOM

- Material procurement through reputable channels like first-level agents

- Capability to provide origin certificates from first-level agents

- Centralized procurement advantage for shorter cycles and stocking benefits

- Complete original technical support provided