PCB Reinforcement Materials Overview

Introduction

PCB circuit boards play a critical role in machinery and electrical equipment, serving as essential platforms for software development. Different types of machinery and equipment utilize various PCB materials for their operations. Rigid printed circuit boards (RPCB) can be classified into different types based on their reinforcement materials. Here, we will delve into the three primary categories of PCB reinforcement materials:

1. Phenolic PCB Paper Substrate

Phenolic PCB paper substrate comprises paper pulp, wood pulp, and sometimes cardboard, V0 board, flame-retardant board, and 94HB. The primary material is wood pulp fiber paper bonded with phenolic resin. While not fireproof, these substrates are cost-effective, lightweight, and punchable. Examples include XPC, FR-1, FR-2, and FE-3, with 94V0 being a flame-retardant variant.

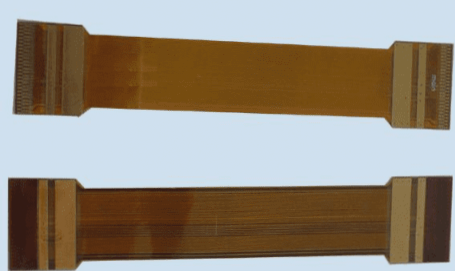

2. Composite PCB Substrate

Composite PCB substrates incorporate wood pulp fiber paper or cotton pulp fiber paper as reinforcement, combined with glass fiber cloth for surface reinforcement. These materials are bonded with flame-retardant epoxy resin. Common examples include single-sided half-glass fiber 22F, CEM-1, and double-sided half-glass fiber board CEM-3, which are popular composite base copper-clad laminates.

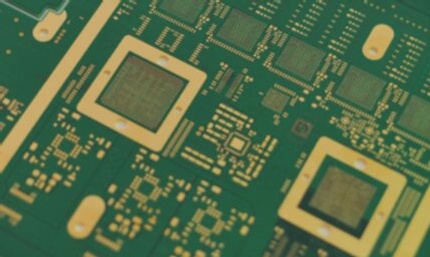

3. Glass Fiber PCB Substrate

Glass fiber PCB substrates utilize epoxy boards, glass fiber boards, FR4, and fiber boards. Epoxy resin acts as the binder, while glass fiber cloth serves as the reinforcing material. These boards offer high working temperatures and are resistant to environmental factors. They are commonly used in power supply boards, high-level circuit boards, computers, peripheral equipment, and communication devices.

Solder Joint Aging in PCBA Processing

Introduction

Solder joints in PCBA processing are prone to aging, leading to potential reliability issues. Understanding the reasons behind solder joint aging is crucial for enhancing equipment reliability and design optimization. Here are three primary reasons for the aging of solder joints:

1. Solder Joint Failure Caused by Welding Process

Issues during welding and cleaning processes can result in solder joint failures. Production and installation stages may suffer from equipment limitations and human errors, leading to defects like false welding and solder short circuits. Mechanical damage from collisions, vibrations, and thermal stress can also impact joint reliability. Corrosion and excessive cleaning further contribute to reliability issues.

2. Failure Caused by Aging

Intermetallic compounds (IMCs) form at the solder-substrate interface during aging, affecting joint microstructure. IMC layer growth can lead to micro-cracks and brittleness, impacting joint reliability. Thermal expansion differences between materials can induce strain, potentially causing failure. Adding trace lanthanum to solder alloys can reduce IMC thickness, enhancing thermal fatigue life and reliability.

3. Failure Caused by Thermal Cycling

Effects of Thermal Cycling on Solder Joints in PCBs

During operation, interruptions in the power supply circuit and fluctuations in temperature can have a significant impact on the reliability of solder joints in printed circuit boards (PCBs). The mismatch in thermal expansion coefficients between different materials used in PCB assembly can induce stress and strain in solder joints.

For example, in surface mount technology (SMT), the coefficient of thermal expansion (CTE) of A1203 ceramic is 6 × 10^-6 °C^-1, while that of epoxy resin/glass fiber substrate is 15 × 10^-6 °C^-1. This difference in CTE values means that temperature changes can lead to varying levels of stress and strain in solder joints, typically ranging from 1% to 20%.

Unlike through-hole technology (THT) processes where flexible pins can absorb some of the strain, in SMT, solder joints bear the brunt of the strain. This can result in the initiation of cracks in the solder joints, eventually leading to failure of the PCB.