Advancement of China’s PCB Industry in the Electronic Information Sector

With the continuous progress in science and technology, China’s electronic information industry is experiencing rapid growth. The domestic printed circuit industry, after years of hard work, has become a crucial foundation for China’s electronic information sector. This has positioned the PCB industry to offer extensive opportunities for further development in China.

Challenges Faced by China’s PCB Industry

- Many Chinese PCB companies rely heavily on imported technology for high-end products, hindering domestic technological independence.

- The lack of advanced technology results in high production costs for premium products, limiting their competitiveness in the local market.

- Industrial standards are absent in China’s PCB sector, impacting its ability to showcase capabilities and compete globally.

- Insufficient market presence makes it challenging for Chinese PCB firms to invest significantly in research and development.

Importance of PCB Reverse Engineering

For the advancement of China’s electronics industry, focusing on PCB reverse engineering research is essential. Replicating printed circuit boards through reverse engineering can provide access to advanced technology at a lower cost, driving innovation and development.

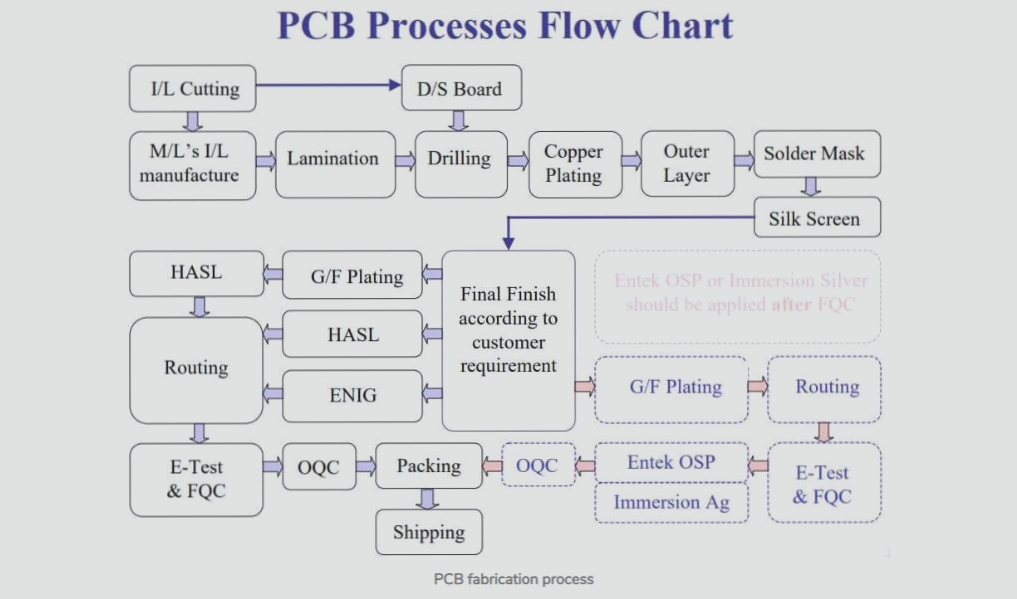

Process of PCB Reverse Engineering

Reverse engineering companies analyze circuit boards using innovative techniques to recreate technical files, BOM files, schematic files, and other essential documents. These files are then utilized in manufacturing, soldering, testing, and debugging to produce precise replicas of the original circuit boards.

Ensuring Future Growth in China’s Electronics Industry

Despite facing risks from foreign high-end products, China’s electronics industry must focus on continuous innovation in PCB reverse engineering. By prioritizing technological advancements and quality services, companies can seize opportunities, adapt to market trends, and provide robust support for industry development.