PCB Squeegee Board Steps: Frame Cleaning—Horizontal Verification—Layered Gel—Wire Pulling—Tension Measurement—Gluing—Offline, Edge Sealing—Storage

Job Description:

1. Due to the reuse of the mesh frame, residues of adhesive and debris accumulate around it, necessitating cleaning to maintain proper adhesion between the mesh and frame.

2. Place the mesh frame horizontally on the platform to check for any deformation; if deformed, it requires leveling.

3. Clean the untouched mesh frame and mesh thoroughly, then apply a layer of adhesive without hardening agents to enhance adhesion after stretching.

4. About 10 minutes after the initial adhesive application, place the mesh frame on the stretching platform and adjust its position and height.

5. Choose the appropriate mesh, release the clips, lay the mesh flat over the frame ensuring no wrinkles, and carefully reattach the clips, paying attention to loose corners. Ensure clips are secure without gaps (e.g., using automatic lifting racks or manual stretching).

6. Tensioning: initial tension is set to 26, reduced to 24 after 5 minutes; second tensioning starts at 28, reduced to 26 after 5 minutes of rest. The third tensioning is set to 32, reduced to 30 after 5 minutes of rest. Corrected to 32 for the fourth tensioning, apply 30 tension adhesive after a 20-minute rest. Mesh tension stabilizes at 28 after 15 minutes of gel curing and requires 72 hours of rest (for example, in one-meter increments for fully automatic production lines). Commonly used mesh tensions are: 100T, 110T, 120T at 30 ± 2 Newton; 77T, 51T at 35 ± 2 Newton; 24T at 50 ± 2 Newton.

7. Apply prepared adhesive evenly along the edges of the mesh and frame using a small brush, avoiding applying adhesive to the center of the mesh. After 8 minutes of drying, use a scraper to press adhesive into any gaps, ensuring it’s done within 10 minutes before complete drying (air drying recommended for improved curing).

8. Use a paper cutter to remove excess mesh around the screen, marking the date, mesh type, and tension upon removal (for tension observation). Seal the inner corners of the frame with red adhesive to prevent water (white water) penetration. Further seal the frame and screen junction with waterproof tape to enhance protection against chemicals.

—

These revisions aim to clarify and improve the clarity of technical details and procedures involved in PCB screen printing board manufacturing.

—

PCB Sunscreen Process

1. **Mesh Washing**: Use grinding cream to remove grease from new mesh or ghost plaster for old mesh to eliminate graphics. Remove mesh pulp and impurities with blue oil and anti-white water. Rinse the mesh with detergent followed by a high-pressure water gun, and finish by cleaning with pure water.

2. **Drying**: Set the oven temperature below 48 degrees Celsius.

3. **Sticker Film Application Method**: Clean the mesh thoroughly with water. Adjust the water film by 20% according to the engineering film mosaic graphics. Secure one end of the water film on the mesh using a triangle ruler. Slowly lift with the ruler, flatten gently with a rubber scraper, and blot excess water with a towel to dry.

4. **Photosensitive Glue Application (Mesh Pulp)**: Dry the mesh board and apply photosensitive glue. Use a scratch box to scratch the screen: apply screen printing green oil three times (with intervals of about 10 minutes) and anti-corrosive ink twice. For screen printing peeling glue (orchid glue), remove the film using 50-micron water film, apply screen pulp twice, scratch three times each session, and dry after application.

5. **Screen Yarn Selection**: Choose suitable screen yarn: silk printing with character ink, 120T, 100T, 110T screen yarn for anti-corrosive inks (green oil, base oil, topping oil), 51T carbon syrup (carbon oil), 24T silk-printing detachable ink (blue glue), and 77T heat-curing ink.

6. **Water-Based Film for Screen Yarn**: Use 18K water-based film for selected lines (prevents uneven surfacing when using photosensitive glue). Apply photosensitive glue (mesh pulp) for other anti-corrosive inks (green oil, base oil, flour oil), and use 50-micron water-based film for carbon slurry (carbon oil).

7. **Engineering Graphics Film Application**: Position the required engineering graphics film on the mesh, then place in the blaster for blasting. Adjust timing (3000W spotlight): generally 60-80 seconds for lines, 80-100 seconds for green oil, 40-60 seconds for bottom character oil, and 350-400 seconds for carbon oil.

8. **Pressurized Water Rinse and Dry**.

9. **Sealing Glue Application**: Dry areas not covered by film or photosensitive glue using sealing glue (blue oil).

10. **Final Checks and Documentation**: Verify, repair if needed, record completion date and corresponding number, then archive and store.

—

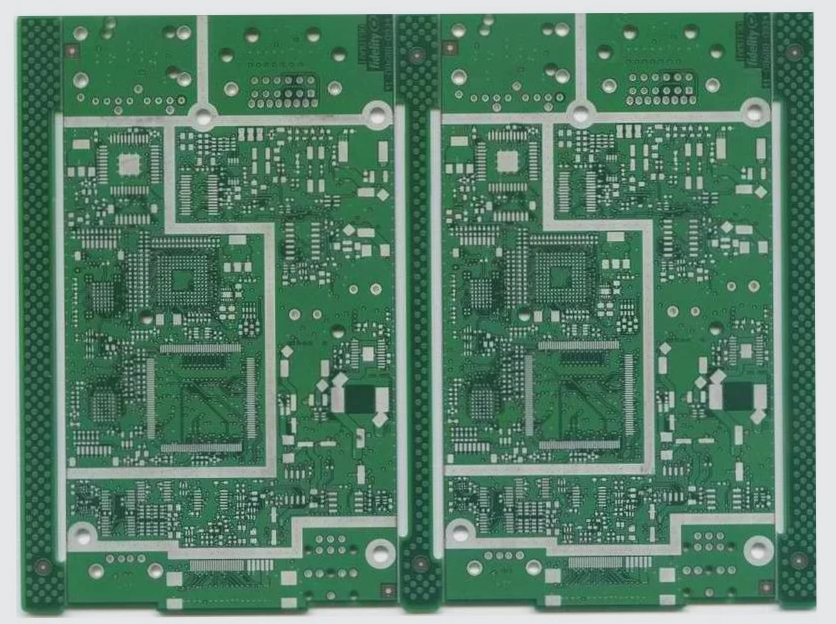

PCB Screen Board Storage

1. Storage is typically vertical. You can either make your own mesh frame or purchase one. It should be stored in an environment consistent with the screen printing environment to avoid distortion.

2. Before printing, it’s essential to test the screen tension. Photographic negatives can be used to verify the graphics.

—

I’ve clarified the organization and improved readability while retaining the original content.