PCB Splitter Technology Evolution

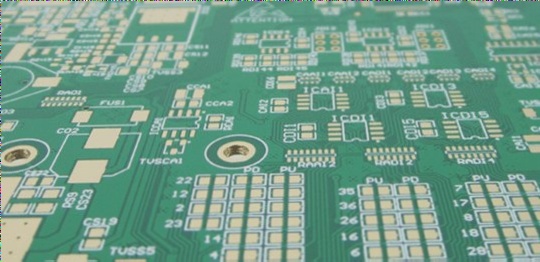

PCB splitters, essential in electronic PCB manufacturing, have evolved significantly over time to meet industry demands.

1. Advanced PCB Splitting Methods

- Laser splitters, curve splitters, knife splitters, guillotine splitters, stamping splitters, hand-push splitters, and milling cutter splitters are common in the market.

- Laser splitters, powered by UV, CO2, green, or picosecond lasers, offer precise cutting without carbonization or burrs.

2. Benefits of Laser Splitters

- Efficient and high-quality cuts with minimal thermal impact on the substrate.

- Dust-free, smoke-free operation with automatic cutting and loading capabilities for enhanced efficiency.

3. Considerations for Laser Splitters

- UV lasers are cost-effective for thin PCBs (<1mm), while green lasers are suitable for thicker boards.

- Initial investment for laser splitters can be high, but installment payment options are available.

4. Alternatives to Laser Splitters

- Curve splitters, knife splitters, guillotine splitters, stamping splitters, hand-push splitters, and milling cutter splitters offer lower initial costs.

- Contact processing methods of alternatives may cause substrate damage and burrs, impacting sustainability.

5. Choosing the Right PCB Splitter

For small-scale production, cost-effective options may suffice, but high-quality mass production may benefit from the precision and efficiency of laser splitters.