Everything You Need to Know about PCB Testing Methods

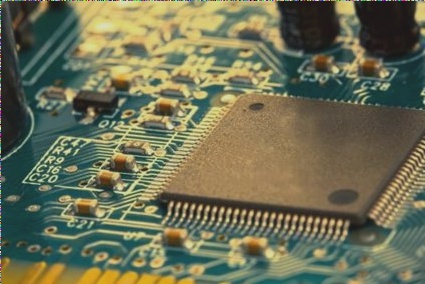

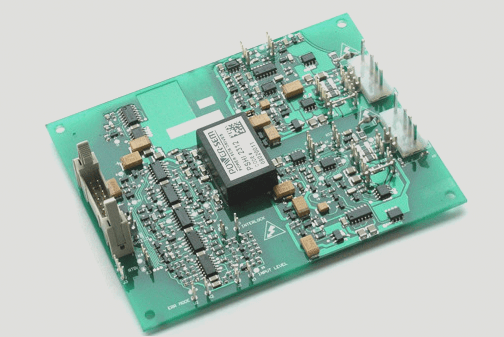

What is the PCB test and why testing it is necessary?

When you want to buy a printed circuit board (PCB), you know what will be the cost of failure. It would be a big let-down if your PCB malfunctions or worse, just stop working. This means all the money goes down the drain and equipment along with it!

This can happen due to poor designing of the circuit or bad quality of the PCB. That is why the PCB testing method must be part of the manufacturing process.

[wpi_designer_button twin_id=2164]

So, now that the importance of PCB testing is realized, we begin to wonder what the method is for it. The truth is that there is more than one! And sometimes it’s hard to find which method will work for you. So, let’s have a look at the testing methods that you can employ to test your printed circuit board PCB.

Key components analyzed during PCB testing?

When a Printed Circuit Board is tested, it means that the circuit design is being tested. The circuit is nothing but a combination of some electronic components. It is important that we first see what some of these components are:

- Capacitors

- Resistors

- Diodes

- Fuses

- Inductor

- IC

- Transistor

- Relay

These are the components that are required to be tested for any kind of irregularity or problem.

List of Printed circuit board testing procedures

PCB Testing Method – 1

(IN-CIRCUIT TESTING)

The most effective method for PCB testing might just be In-circuit testing (ICT). An ICT works by powering up and actuating the circuitry on the PCB. The test is designed to provide 100 percent coverage but the rest of the time you will end up with 85 to 90 percent coverage. The upside of this is that the results don’t require human effort and are thus free of human error!

Steps for testing:

- Laying of fixed probes

- Checking connections

- Start the test

Access points that are already a part of the printed circuit board allow for connection with the ICT testing probes. It is important to ensure that the connection is strong by laying a bit pressure on it.

Best for:

- An ICT is best suited for Ball Grid Arrays (BGAs) or big connections.

- Test for the final product and cannot be used in between the process of manufacturing

PCB Testing Method – 2

(FLYING PROBE TESTING)

Flying probe testing is a cost-effective method for PCB testing. It doesn’t require the use of power like ICT. It can be used to search for individual problems in the circuit like:

- Shorts

- Capacitance

- Resistance

- Inductance

- Opens

- Diode problems

Steps for testing:

- Needles attached to a probe on an x-y grid (obtained from CAD)

- Probes can be moved around the circuit board at a different point or individual components to find the individual result.

[wpi_designer_button twin_id=2164]

PCB Testing Method – 3

AUTOMATED OPTICAL INSPECTION (AOI)

One of the initial and quick methods for PCB testing is AOI. It can be used to detect the issues arising in the initial stage of manufacturing. The procedure for testing is simple.

Steps for testing:

- AOI snaps photos of the circuit board under test

- Comparison of photos with a detailed schematic

- If the board matches the schematics to a certain percentage, then it passes. If below that particular percentage, flagged to be inspected by a technician.

Best for:

AOI is best suited for early issues that might develop in the board during the manufacturing process. However, the user should not solely rely on AOI for testing. It’s better that this test may be used in combination with other tests like ICT or Flying Probe method.

PCB Testing Method 4

(BURN-IN TESTING)

As obvious from the name, this is a bit intense form of testing the PCBs. Burn-Inn testing works by passing high power through the electronic at its maximum capacity.

Its main utility is found in early on detection of failures and to establish load capacity. But care should be exercised as the test can prove destructive to the parts of the PCB.

Steps for testing:

- Pushing high power through the PCB at its maximum capacity.

- Power ran through for 48-168 hours.

- If the board fails, it’s known as Infant Mortality.

Best for:

The Burn-In test is not suited for all circumstances. It can be used for:

- Testing a product to its limit before launching in the market

- Early on detection in the initial phase of manufacturing.

- The thing to remember is that Burn-In testing can reduce the life of your PCB. So it should be used when really required and not unnecessarily.

PCB Testing Method 5

(X-RAY INSPECTION)

X-Ray testing is used to locate the faults in the connection which are hidden from the eye. These might be the connections that are underneath the chip package.

There are 2-D and 3-D AXI tests. 3-D offers a faster testing period. It should be considered more of an inspection technique for fault tracing.

Tested for:

- Solder connections

- Barrels

- Internal traces

Best for:

- Inspecting different layers of the board which is otherwise not visible to the inspector’s eye.

- Mostly useful for electronics contact manager rather than the user himself.

- The thing to remember is that Burn-In testing can reduce the life of your PCB. So it should be used when really required and not unnecessarily.

PCB Testing Method 6

(Functional testing)

Some users prefer the old school functional test over other modern tests. Functional Testing (FCT) tests the PCB to check whether it will perform the functions that it is designed to provide or not. The Electronics Contract Manager (ECM) makes use of this method to check and make sure that your product will power up. This is usually employed as the very last step to test the working of the product before it’s shipped off to the user.

Requirements for testing:

A few things are required for conducting this test by the ECM:

- Requirements for UL, MSHA, and other standards

- External pieces of equipment

- Fixtures

- Parameters for testing are provided by the customer. ECM can help you develop the procedure for test if the customer wants.

Best for:

- The final test before launching the product in the market.

- It provides great quality assurance but requires time.

PCB Testing Method 7

(Other Functional Tests)

Apart from the PCB tests mentioned above, there are other types of functional tests that can be used for checking the working of PCBs.

This test is used to check the behavior of a PCB in the user environment. But, of course, this varies from user to user.

These tests include:

PCB Contamination test: this test detects the presence of ionics on PCB which are a potential source of corrosion.

Solderability test: Used to check the sturdiness of the surface.

Micro-sectioning analysis: Finds open, shorts, or other failures.

Peel test: finds the amount of force required to remove the surface of lamination from the PCB.

Time-domain reflectometer: It’s used to detect failures in High-frequency boars.

Best for:

- Reduces Customer support.

- It can be used well with other tests like ICT and flying probes.

- May be used as an alternative for other costly tests.

- Good for detecting functional failures and component values.

Key take away:

You need to ask yourself, “what is your requirement from the PCB?” before deciding to conduct a test. Different tests offer different results at different prices. After reading through our guide, you will definitely be able to identify the right method for your PCB testing. WellCircuits Electronics can be your trusted and reliable source of your Printed Circuit Boards needs.

[wpi_designer_button twin_id=2164]