Effective Heat Dissipation in PCB Design

Electronic equipment generates heat during operation, which can lead to overheating and decreased performance if not properly managed. Efficient heat dissipation on the circuit board is essential to prevent device failure.

Key Considerations for PCB Heat Dissipation:

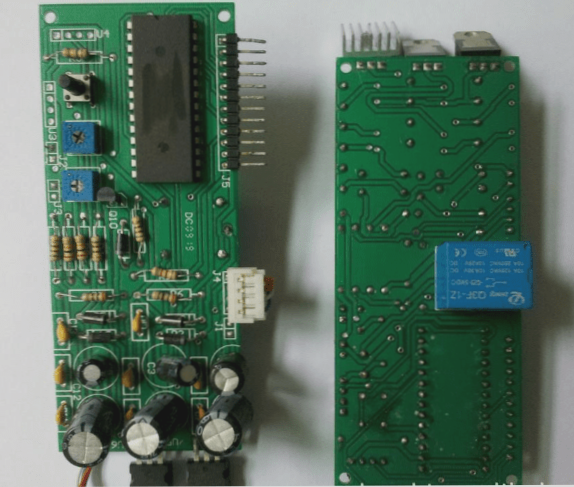

- 1. Design and centralize high-heat components on a separate PCB board for dedicated ventilation.

- 2. Distribute heat evenly on the PCB surface to avoid hotspots and ensure adequate airflow.

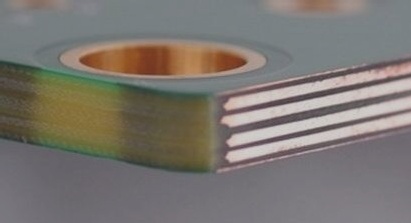

- 3. Keep heat transfer paths short and maximize cross-sectional area for heat dissipation.

- 4. Consider thermal radiation effects and isolate heat-sensitive components.

- 5. Optimize ventilation direction for forced and natural cooling.

- 6. Maintain consistent airflow direction for effective heat dissipation.

- 7. Provide ample space between intake and exhaust areas.

- 8. Position heating devices above the product and in the airflow path when possible.

- 9. Avoid placing high-heat components in corners and edges; use radiators strategically.

Adding radiators to devices can also enhance heat dissipation efficiency.