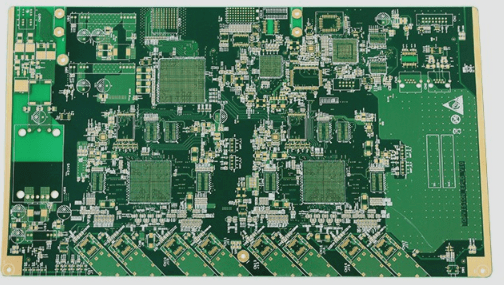

1. Printed circuit board (PCB) surface treatment technology refers to the process of artificially forming a surface layer on the PCB components and electrical connection points that differs from the mechanical, physical, and chemical properties of the substrate.

2. Its purpose is to ensure optimal solderability and electrical performance of the PCB.

3. Because copper tends to oxidize in the air, which can severely affect the solderability and electrical properties of the PCB, surface treatment is necessary.

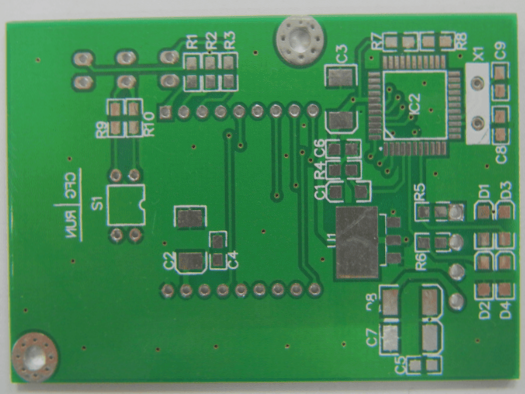

4. Hot air leveling (HASL) is a common surface treatment method, involving the application of a tin-lead alloy.

5. For perforated devices, wave soldering is often the preferred method due to its effectiveness.

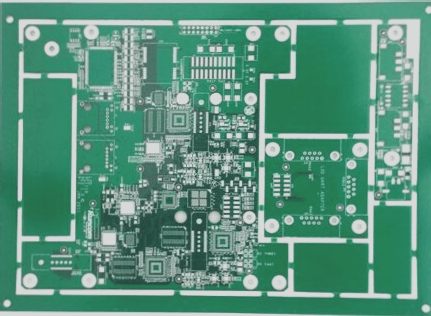

1. The use of hot-air solder leveling (HASL) surface treatment technology is often sufficient for wave soldering process requirements. However, for applications requiring high junction strength, especially for contact connections, nickel/gold electroplating is commonly used. HASL remains a prevalent surface treatment technology worldwide, but three primary factors drive the electronics industry to explore alternatives: cost, evolving process requirements, and lead-free regulations.

2. Cost-wise, many electronic components, such as those in mobile communications and personal computers, have become common consumer goods. To remain competitive, products must be sold at or below cost. With the advent of SMT assembly technology, PCB pads now require screen printing and reflow soldering during assembly. Initially, HASL was used for PCB surface treatment, but as SMT devices have shrunk, the limitations of HASL have become apparent. HASL-treated pads often lack flatness and coplanarity, failing to meet the fine-pitch pad requirements. Environmental concerns also center on lead’s potential impact.

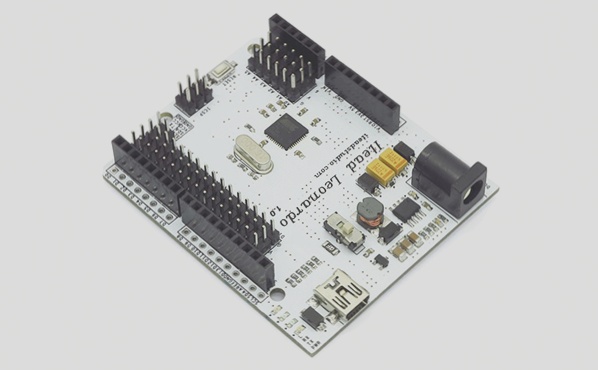

3. Organic Anti-oxidation (OSP)

4. Organic solderability preservative (OSP) is an organic coating designed to prevent copper from oxidizing before soldering, thus protecting PCB pads’ solderability. After OSP treatment, a thin organic compound forms on the copper surface, safeguarding it from oxidation. Benzotriazoles OSP typically has a thickness of around 100 Å, while Imidazoles OSP is thicker, generally about 400 Å. The OSP film is transparent and not easily detectable by the naked eye. During assembly (reflow soldering), OSP dissolves into the solder paste or acidic flux, exposing the active copper surface and forming Sn/Cu intermetallic compounds between components and pads. OSP is environmentally friendly as it does not contribute to lead pollution.

5. Limitations of OSP:

6. OSP’s transparency and colorlessness make inspection challenging, as it is difficult to determine whether a PCB has been coated with OSP.

7. OSP itself is an insulator and does not conduct electricity. Benzotriazoles OSP, being relatively thin, may not impact electrical testing, but Imidazoles OSP’s thicker film can affect electrical tests. OSP is unsuitable for electrical contact surfaces, such as keyboard keys.

8. Stronger flux is required during the welding process with OSP; otherwise, the protective film may not be removed, leading to soldering defects.

9. During storage, OSP-coated surfaces must be protected from acidic substances and high temperatures to prevent volatilization of the OSP.

2. Its purpose is to ensure optimal solderability and electrical performance of the PCB.

3. Because copper tends to oxidize in the air, which can severely affect the solderability and electrical properties of the PCB, surface treatment is necessary.

4. Hot air leveling (HASL) is a common surface treatment method, involving the application of a tin-lead alloy.

5. For perforated devices, wave soldering is often the preferred method due to its effectiveness.

1. The use of hot-air solder leveling (HASL) surface treatment technology is often sufficient for wave soldering process requirements. However, for applications requiring high junction strength, especially for contact connections, nickel/gold electroplating is commonly used. HASL remains a prevalent surface treatment technology worldwide, but three primary factors drive the electronics industry to explore alternatives: cost, evolving process requirements, and lead-free regulations.

2. Cost-wise, many electronic components, such as those in mobile communications and personal computers, have become common consumer goods. To remain competitive, products must be sold at or below cost. With the advent of SMT assembly technology, PCB pads now require screen printing and reflow soldering during assembly. Initially, HASL was used for PCB surface treatment, but as SMT devices have shrunk, the limitations of HASL have become apparent. HASL-treated pads often lack flatness and coplanarity, failing to meet the fine-pitch pad requirements. Environmental concerns also center on lead’s potential impact.

3. Organic Anti-oxidation (OSP)

4. Organic solderability preservative (OSP) is an organic coating designed to prevent copper from oxidizing before soldering, thus protecting PCB pads’ solderability. After OSP treatment, a thin organic compound forms on the copper surface, safeguarding it from oxidation. Benzotriazoles OSP typically has a thickness of around 100 Å, while Imidazoles OSP is thicker, generally about 400 Å. The OSP film is transparent and not easily detectable by the naked eye. During assembly (reflow soldering), OSP dissolves into the solder paste or acidic flux, exposing the active copper surface and forming Sn/Cu intermetallic compounds between components and pads. OSP is environmentally friendly as it does not contribute to lead pollution.

5. Limitations of OSP:

6. OSP’s transparency and colorlessness make inspection challenging, as it is difficult to determine whether a PCB has been coated with OSP.

7. OSP itself is an insulator and does not conduct electricity. Benzotriazoles OSP, being relatively thin, may not impact electrical testing, but Imidazoles OSP’s thicker film can affect electrical tests. OSP is unsuitable for electrical contact surfaces, such as keyboard keys.

8. Stronger flux is required during the welding process with OSP; otherwise, the protective film may not be removed, leading to soldering defects.

9. During storage, OSP-coated surfaces must be protected from acidic substances and high temperatures to prevent volatilization of the OSP.