The Significance of PCB Tool Holes in Circuit Board Design

A skilled detective is known for noticing minute details that others may overlook, which can be crucial in solving mysteries. Similarly, in PCB design, seemingly insignificant elements like tool holes play a vital role in ensuring the functionality and precision manufacturing of the board.

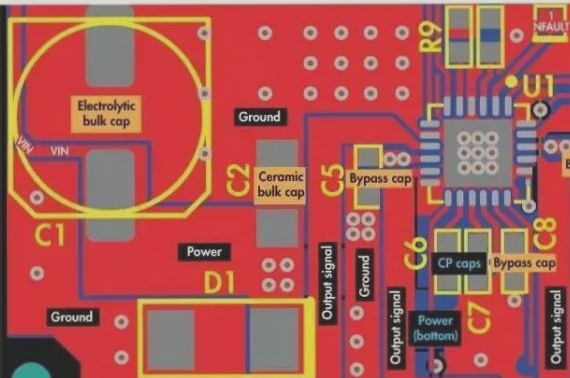

While tool holes may initially appear like standard through-holes on a circuit board, they serve essential functions that are integral to the overall design. These holes facilitate hardware connections, aid in the fabrication process, and are crucial for assembly. In PCB design, it is common practice to incorporate various holes of different sizes, each serving specific purposes.

Most of these holes are used for interconnecting electrical signals between layers, soldering components, and mounting hardware. Tool holes, also known as “mounting holes,” are essential for hardware connections and can be part of a component’s footprint pattern or designated separately. Components such as connectors may require mounting hardware for added support, especially for connectors that endure stresses from cable insertion and removal.

Additionally, some components need mounting hardware for electrical grounding or heat dissipation through the board’s internal layers. Isolation holes are also necessary for installing the PCB into its system, securing the required hardware or brackets. Strategically positioned tool holes streamline manufacturing stages like reflow soldering, wave soldering, and automatic optical inspection, and are utilized during testing procedures if needed.

Manufacturers must ensure the inclusion of tool holes in the design to support various manufacturing phases. These holes are tailored for hardware installation and must meet precise design parameters to fulfill their functions effectively. Designers also need to consider other elements like solder paste pads, solder resistance film, screen printing marks, and reference pads for PCB alignment during automated assembly.

Addressing all these aspects in PCB design can be challenging, but it is what sets apart a proficient PCB design engineer.