1. The main reason for PCB deformation is the high temperature that softens the FR4 sheet. To address this issue, I found a suitable material for use as a furnace tray.

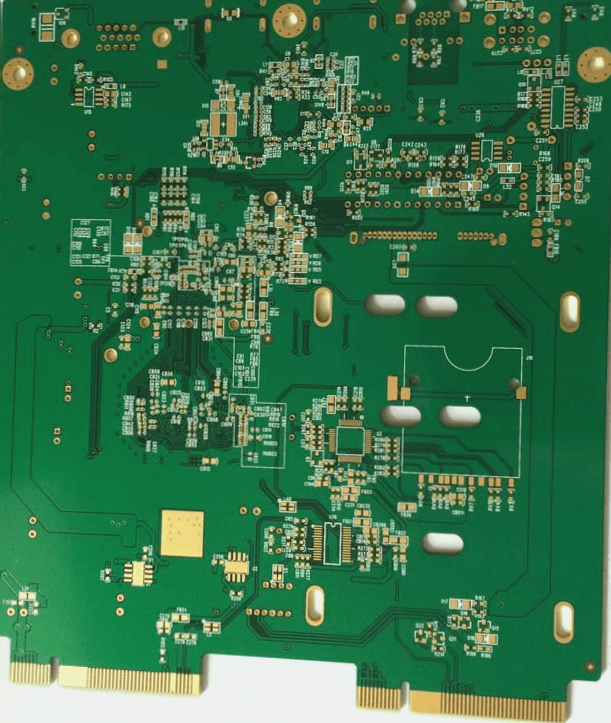

2. With the advancement of science and technology, electronic products are becoming thinner and more compact, leading to increasingly slim electronic components. This trend is also reflected in the decreasing thickness of PCB circuit boards (PCBs).

3. Such thin PCBs are particularly susceptible to deformation when exposed to the high temperatures of SMT Reflow (reflow furnace), which can even cause components to fall off during the process.

4. To mitigate these challenges, innovative engineers have developed the Reflow Carrier (furnace tray) to support PCB circuit boards, thereby reducing the likelihood of deformation.

5. A significant portion of PCB deformation occurs when the high temperature softens the FR4 material. Therefore, it’s essential to identify a material with the following characteristics to serve effectively as a furnace tray:

—

Let me know if you need any further changes!