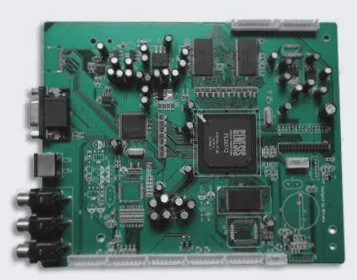

1. PCBA processing involves the production of a finished product. Understanding SMT patch processing is crucial in this context. Essentially, PCBA is a completed product created from a PCB light board through various stages including SMT patching, THT plugging, PCBA testing, quality inspection, assembly, and more. This process is often referred to as PCBA. It enables the realization of the designer’s intended functionality and is integral to nearly all electronic products, such as smart home devices, AR, VR systems, medical equipment, and others, which rely on PCBA boards.

2. The methods of PCBA processing and assembly primarily depend on the type of surface mount components, the kinds of components being installed, the conditions of the processing equipment, and the specific production line setup. PCBA processing can be categorized into three main types: single-sided mixed assembly, double-sided mixed assembly, and full-surface assembly, totaling six distinct assembly methods.

3. **Single-sided mixed**

The circuit board used in this method is a single-sided PCB. Single-sided hybrid assembly means that SMT patch and THT plug-in components are placed on different sides of the PCB. The soldering surface is on one side, while the patch components are on the opposite side. This assembly method utilizes a single-sided PCB and typically employs wave soldering (currently, double wave soldering is commonly used). There are two specific assembly techniques:

(1) **Paste first, then insert:** Mount SMC/SMD components on the B side (the soldering side) of the PCB first, then insert the THC components on the A side.

(2) **Insert first, then paste:** Insert THC components on the A side of the PCB first, then mount the SMD components on the B side. This method is commonly used in the assembly of TVs, radios, and other products.

4. **PCBA processing**

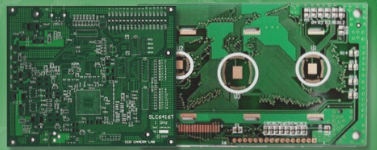

5. **Double-sided mixed**

1. The circuit board used for assembly is a double-sided PCB. SMT patch and DIP plug-in components can be mixed and placed on the same side or both sides of the PCB. Double-sided hybrid assembly involves using double-sided SMT, double wave soldering, or reflow soldering. In this type of assembly, there is also a distinction between first and second SMC/SMD. Generally, the choice depends on the type of SMC/SMD and the size of the PCB. Typically, the first paste method is more commonly used. There are two commonly used assembly methods for this type:

2. (1) SMT components and DIP components on the same side: SMT chip components and DIP plug-in components are placed on the same side of the PCB; DIP plug-in components can be on one or both sides. Generally, DIP components are inserted after the SMC/SMD components are applied first.

3. (2) DIP components with SMT components on one side and both sides: Place the surface mount integrated circuits (SMIC) and THT components on side A of the PCB, and place the SMC components and small outline transistors (SOT) on side B.

4. For the single-sided and double-sided mixed assembly of PCBA processing, all circuit boards are assembled into single-sided and double-sided PCBs (or ceramic substrates). These assemblies include only SMT components and no THT components. Since current components have not yet fully transitioned to SMT, such assembly configurations are rare in practical applications. There are two assembly methods for this type: single-sided surface assembly and double-sided surface assembly. Do you understand the assembly methods for PCBA processing based on the above content?