The Skills of Printed Circuit Board Assembly

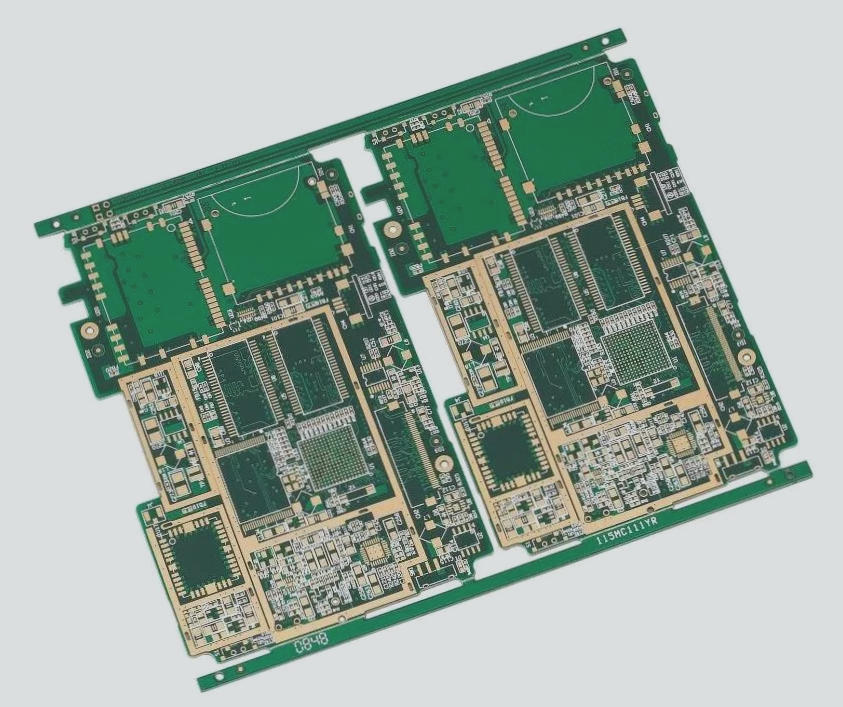

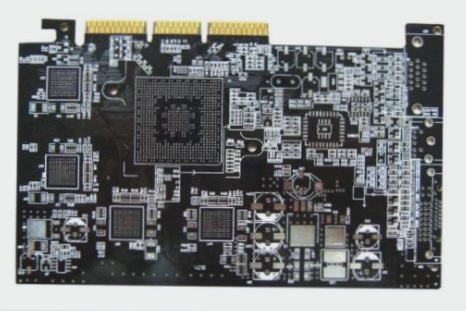

Printed circuit boards (PCBs) are essential components in electronics, made of copper and usually green in color. Assembly of PCBs is a technical process crucial for their proper functioning.

PCBA Through-Hole Technology

One of the traditional assembly methods is through-hole technology, combining manual and automatic procedures. Here’s how it works:

- Component Placement: Engineers manually place components on the PCB according to design files, ensuring precise positioning.

- Check and Correct: Inspection is done to verify component orientation and placement accuracy before soldering.

- Wave Soldering: The final step involves passing the board through molten solder to securely attach components.

For example, engineers must ensure correct component polarity and wear anti-static wrist straps when handling sensitive components like integrated circuits. Inspection and rectification are crucial before wave soldering to fix any issues.

Surface Mount Technology (SMT) Method

In SMT assembly, smaller and more sensitive components are used, such as diodes and resistors, requiring different equipment and materials compared to through-hole soldering.

This method offers higher manufacturing efficiency through pick and place, solder paste printing, and reflow soldering processes:

- Solder Paste Printing: Solder paste is accurately applied to the board using a stencil or solder mask.

- Component Placement: Components are placed on designated pads using a machine for secure attachment.

- Reflow Soldering: The board with components goes through a reflow oven to melt and solidify the solder, attaching all components securely.

Hybrid Technology

As electronics advance, circuit boards become smaller and more complex, often featuring a mix of through-hole and surface mount components. Managing this hybrid technology is crucial for optimizing manufacturing processes.

Printed Circuit Board Assembly Best Practices

- Familiarize Yourself with File Formats

- Early Communication with Your PCB Supplier

- Diversify Suppliers and Beware of Offshore Risks

- Thorough Part Labeling for Error Prevention

- Optimize Manufacturing Test Design

- Validate Quality Before Bulk Ordering

Ensure your PCB manufacturer is well-versed in the CAD and Gerber file formats you plan to use. Not all manufacturers support every format, so this step is crucial for seamless production.

Engage with your PCB assembly supplier during the design phase to gain valuable insights and understand industry standards and emerging technologies. Early collaboration can lead to a superior end product.

While offshore suppliers may offer cost benefits, be cautious of potential risks like substandard components. Diversify your supplier base to mitigate risks and ensure consistent quality.

Label all components clearly with names and numbers to minimize errors and confusion during troubleshooting. Proper labeling practices save time and enhance efficiency.

Invest time in effective manufacturing test design to reduce costs, streamline processes, and identify issues early on. This proactive approach ensures smooth production progress.

Prioritize quality over discounts when placing large orders. Test the final circuit board product to verify standards before committing to bulk purchases. Compare services from different assemblers for an informed decision.