PCBA Processing Industry Insights

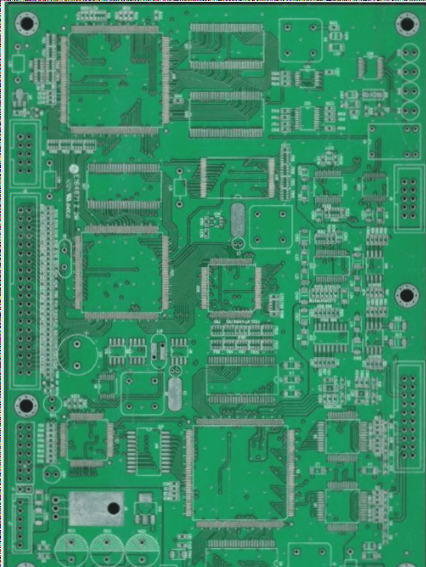

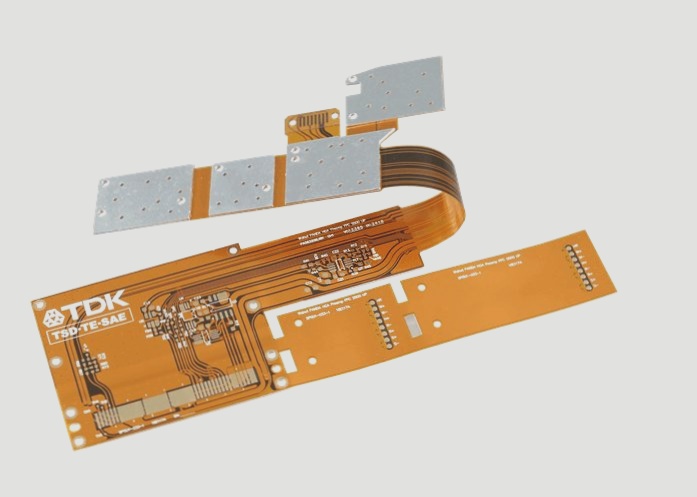

China’s electronics industry is rapidly evolving, with a focus on integration, miniaturization, and lightweight design in electronic products. This has led to increased demands on manufacturers for advanced technical research and development. PCBA (Printed Circuit Board Assembly) plays a crucial role in assembling electronic components onto circuit boards using surface mount technology (SMT) and DIP (Dual In-line Package) insertion processes.

Key Solutions for PCBA Processing Industry:

-

1. Procurement of High-Quality Components

High-quality electronic components are essential for ensuring the overall quality of circuit boards.

-

2. Advanced Production Equipment

PCBA factories utilize MYDATA automatic SMT production lines with advanced equipment for high-precision production. This includes MYDATA placement machines, solder paste printers, solder paste detectors, wave soldering systems, and inspection instruments for efficient and rapid production.

-

3. Strict Quality Management System

Adherence to quality system standards like TS16949: 2009/ISO9001: 2008 and implementing nine inspection procedures ensures that all products meet stringent quality requirements.

-

4. Efficient Data Management System

Implementing a customized Jindie ERP management system enables real-time monitoring of order production status, ensuring timely delivery and enhancing customer trust.