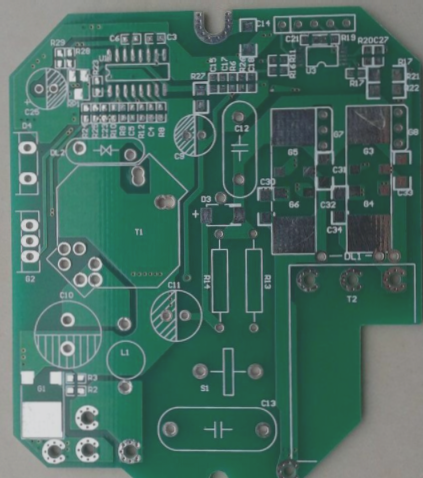

Key Considerations for Successful PCBA Processing

Transportation Guidelines:

- Use anti-static turnover boxes for packaging.

- Employ anti-static pearl cotton as isolation material.

- Maintain a minimum of 10mm spacing between PCB boards and the box, as well as between boards.

- Ensure a placement height of over 50mm from the top surface of the turnover box to avoid pressure on power supply wires.

PCBA Processing and Washing Requirements:

When washing the board surface, ensure it is clean and free from tin beads, component pins, and stains. Solder joints on the plug-in surface must be free of any soldering residues. Protect wires, connecting terminals, relays, switches, and other components prone to corrosion during washing. Avoid cleaning relays with ultrasonic methods.

Considerations During PCBA Processing:

- No components should extend beyond the PCB edge after installation.

- Ensure proper correction of plug-in components tilt after soldering in the tin furnace process.

- Realignment guidelines for various components based on their type and floating height.

- Process requirements for SMT patch processing and component placement.

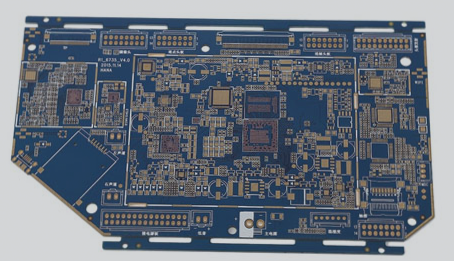

Three Key Elements for PCB Circuit Board Mounting Quality:

- Verify correct components matching the assembly drawing and schedule.

- Ensure accurate placement of components aligned with the land pattern and solder paste.

Proper Pressure for PCB Assembly

When it comes to PCB assembly, one crucial factor to consider is the proper pressure during component placement. The pressure applied should be in line with the Z-axis height of the nozzle. Here’s why it matters:

- Z-axis Height Impact: The Z-axis height plays a significant role in determining the placement pressure. A high Z-axis height results in lower pressure, while a low Z-axis height results in higher pressure.

- Effects of Incorrect Height: If the Z-axis height is too high, the component may not properly adhere to the solder paste, increasing the risk of position shifts during transmission and reflow soldering. On the other hand, if the Z-axis height is too low, there may be excessive solder paste extrusion, leading to issues like solder paste adhesion, bridging, component damage, and misalignment.

- Adjustment Importance: To avoid these issues, it is crucial to appropriately adjust the Z-axis height of the suction nozzle during placement. This adjustment ensures optimal pressure for successful PCB assembly.

Latest Update:

Recent advancements in PCB assembly technology have introduced automated pressure adjustment systems that can dynamically regulate the placement pressure based on real-time feedback. These systems help optimize the Z-axis height and pressure settings, improving overall assembly efficiency and quality.