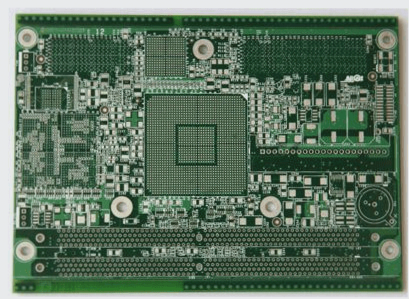

1. **Manual Visual Test**

Manual visual testing involves confirming the placement of electronic components on the PCB circuit board through human observation and comparison. This technology is one of the most widely used online testing methods. However, as output increases and PCB sizes shrink along with electronic components, its applicability is diminishing. The main advantages are low initial costs and no need for test fixtures; conversely, the significant drawbacks include high long-term costs, inconsistent defect detection, challenges in data collection, lack of electrical testing, and visual limitations.

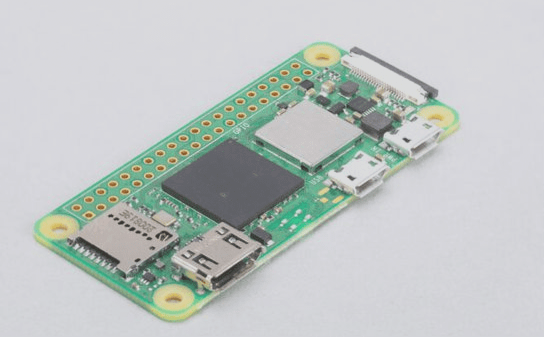

2. **Automated Optical Inspection (AOI)**

This method, also known as automatic visual testing, is typically employed before and after reflow. It serves as a modern approach to identifying manufacturing defects. AOI is particularly effective for checking component polarity and presence. This non-electrical, fixture-free online technology offers advantages such as easy follow-up diagnosis, straightforward program development, and no requirement for fixtures. However, it has limitations, including poor short-circuit recognition and the absence of electrical testing.

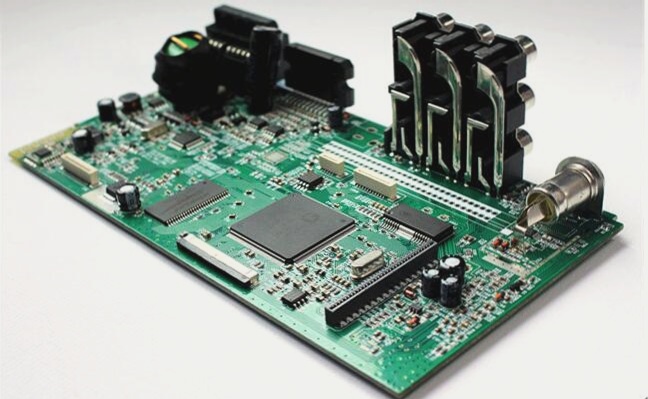

3. **Functional Test**