1. **Bill of Materials**

Insert or mount components strictly according to the bill of materials, PCB silk screen, and outsourcing processing requirements. If materials do not match the bill, PCB silk screen, or conflict with process requirements, or if requirements are vague and operations cannot be performed, contact our company promptly to confirm the correctness of materials and process requirements.

2. **PCBA Foundry Material**

3. **Anti-static Requirements**

1. All components are treated as electrostatic sensitive devices.

2. All personnel handling components and products must wear anti-static clothing, anti-static bracelets, and anti-static shoes.

3. Electrostatic sensitive devices must be packaged in anti-static materials during factory entry and while in storage.

4. Use anti-static work surfaces and containers for components and semi-finished products during operations.

5. Ensure welding equipment is properly grounded, and use anti-static soldering irons; all must be tested before use.

6. Store and transport semi-finished PCB boards in anti-static boxes with anti-static pearl cotton for isolation.

7. Package entire machines without enclosures in anti-static bags.

**Anti-static Requirements for PCBA Processing**

**Third, the Provisions for Component Appearance Mark Insertion Direction**

1. Polarity components must be inserted according to their polarity.

2. For components with silk-screen markings on the side (e.g., high-voltage ceramic capacitors), when inserted vertically, the silk screen should face right; when inserted horizontally, the silk screen should face down. For components with silk-screen markings on the top (excluding chip resistors), when inserted horizontally, the text direction should align with the PCB screen printing; when inserted vertically, the top of the text should face right.

3. For resistors, when inserted horizontally, the error color ring should face right; when inserted vertically, the error color ring should face down; when inserted vertically, the error color ring should face the board.

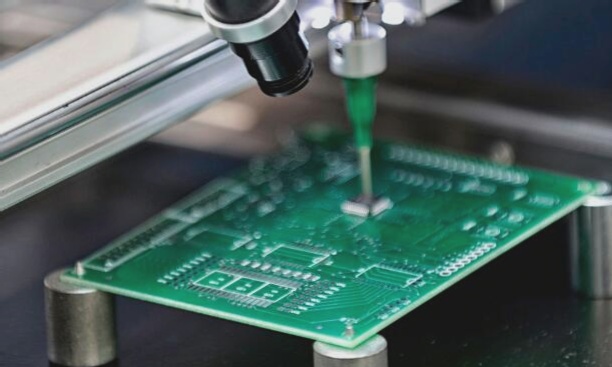

**Fourth, PCB Soldering Requirements**

1. The pin height of plug-in components on the soldering surface should be 1.5–2.0mm. SMD components should be flat against the board surface with smooth, burr-free solder joints that are slightly arc-shaped. The solder should cover more than 2/3 of the height of the solder end but not exceed it. Excessive solder, ball-shaped solder joints, or solder-covered patches are undesirable.

2. Solder joint height: For single-sided boards, solder climbing pins should not be less than 1mm; for double-sided boards, they should not be less than 0.5mm, and solder must fully penetrate.

3. Solder joint shape: Should be conical and cover the entire pad.

**PCBA Soldering Process**

4. The surface of solder joints should be smooth, bright, and free of black spots, flux, debris, spikes, pits, pores, or exposed copper.

5. Solder joint strength: Must be fully wetted to pads and pins with no false or incomplete soldering.

6. Solder joint cross-section: Component leads should not be cut into the solder part as much as possible, and the contact surface between the lead and solder should be free of cracks. No spikes or barbs should be present.

7. Needle base soldering: The needle base must be mounted correctly on the bottom board with proper alignment and direction. After soldering, the floating height should not exceed 0.5mm, and the skew should not exceed the silk screen frame. Rows of needle holders should be neat, with no misalignment or unevenness.

**Five, Transportation**

To prevent PCBA damage during transportation, use the following packaging:

1. Container: Anti-static turnover box.

2. Isolation material: Anti-static pearl cotton.

3. Placement spacing: Ensure a distance greater than 10mm between the PCB board and the box.

4. Placement height: Maintain a space greater than 50mm from the top surface of the turnover box to avoid pressing against the power supply, especially the wire power supply.

**Six, Board Washing Requirements**

The board surface should be clean, free of tin beads, component pins, and stains. Specifically, solder joints on the plug-in surface should be free of soldering residues. Protect the following devices when washing the board: wires, connecting terminals, relays, switches, polyester capacitors, and other corrosive components. Relays must not be cleaned with ultrasonic methods.

**Seven, Component Placement**

All components must remain within the edges of the PCB board after installation.

**Eight, Post-Furnace Repairs**

After passing through the furnace, some plug-in components may become tilted, causing them to extend beyond the silk screen frame due to solder flow. Therefore, repair soldering staff must correct these issues post-furnace.

Insert or mount components strictly according to the bill of materials, PCB silk screen, and outsourcing processing requirements. If materials do not match the bill, PCB silk screen, or conflict with process requirements, or if requirements are vague and operations cannot be performed, contact our company promptly to confirm the correctness of materials and process requirements.

2. **PCBA Foundry Material**

3. **Anti-static Requirements**

1. All components are treated as electrostatic sensitive devices.

2. All personnel handling components and products must wear anti-static clothing, anti-static bracelets, and anti-static shoes.

3. Electrostatic sensitive devices must be packaged in anti-static materials during factory entry and while in storage.

4. Use anti-static work surfaces and containers for components and semi-finished products during operations.

5. Ensure welding equipment is properly grounded, and use anti-static soldering irons; all must be tested before use.

6. Store and transport semi-finished PCB boards in anti-static boxes with anti-static pearl cotton for isolation.

7. Package entire machines without enclosures in anti-static bags.

**Anti-static Requirements for PCBA Processing**

**Third, the Provisions for Component Appearance Mark Insertion Direction**

1. Polarity components must be inserted according to their polarity.

2. For components with silk-screen markings on the side (e.g., high-voltage ceramic capacitors), when inserted vertically, the silk screen should face right; when inserted horizontally, the silk screen should face down. For components with silk-screen markings on the top (excluding chip resistors), when inserted horizontally, the text direction should align with the PCB screen printing; when inserted vertically, the top of the text should face right.

3. For resistors, when inserted horizontally, the error color ring should face right; when inserted vertically, the error color ring should face down; when inserted vertically, the error color ring should face the board.

**Fourth, PCB Soldering Requirements**

1. The pin height of plug-in components on the soldering surface should be 1.5–2.0mm. SMD components should be flat against the board surface with smooth, burr-free solder joints that are slightly arc-shaped. The solder should cover more than 2/3 of the height of the solder end but not exceed it. Excessive solder, ball-shaped solder joints, or solder-covered patches are undesirable.

2. Solder joint height: For single-sided boards, solder climbing pins should not be less than 1mm; for double-sided boards, they should not be less than 0.5mm, and solder must fully penetrate.

3. Solder joint shape: Should be conical and cover the entire pad.

**PCBA Soldering Process**

4. The surface of solder joints should be smooth, bright, and free of black spots, flux, debris, spikes, pits, pores, or exposed copper.

5. Solder joint strength: Must be fully wetted to pads and pins with no false or incomplete soldering.

6. Solder joint cross-section: Component leads should not be cut into the solder part as much as possible, and the contact surface between the lead and solder should be free of cracks. No spikes or barbs should be present.

7. Needle base soldering: The needle base must be mounted correctly on the bottom board with proper alignment and direction. After soldering, the floating height should not exceed 0.5mm, and the skew should not exceed the silk screen frame. Rows of needle holders should be neat, with no misalignment or unevenness.

**Five, Transportation**

To prevent PCBA damage during transportation, use the following packaging:

1. Container: Anti-static turnover box.

2. Isolation material: Anti-static pearl cotton.

3. Placement spacing: Ensure a distance greater than 10mm between the PCB board and the box.

4. Placement height: Maintain a space greater than 50mm from the top surface of the turnover box to avoid pressing against the power supply, especially the wire power supply.

**Six, Board Washing Requirements**

The board surface should be clean, free of tin beads, component pins, and stains. Specifically, solder joints on the plug-in surface should be free of soldering residues. Protect the following devices when washing the board: wires, connecting terminals, relays, switches, polyester capacitors, and other corrosive components. Relays must not be cleaned with ultrasonic methods.

**Seven, Component Placement**

All components must remain within the edges of the PCB board after installation.

**Eight, Post-Furnace Repairs**

After passing through the furnace, some plug-in components may become tilted, causing them to extend beyond the silk screen frame due to solder flow. Therefore, repair soldering staff must correct these issues post-furnace.