Ecological Civilization and Automotive Electronics PCBA Processing

- In today’s rapidly evolving society, the emphasis on constructing ecological civilization and implementing effective ecological environmental protection measures has intensified.

- The ecological environment plays a crucial role in sustaining society and is a key focus for future development.

- Advancements in environmental protection have led to a rise in the adoption of autonomous driving and new energy vehicles.

- Notable companies like Tesla, BYD, and Weilai Automobile are driving growth in customer orders for automotive electronics PCBA processing.

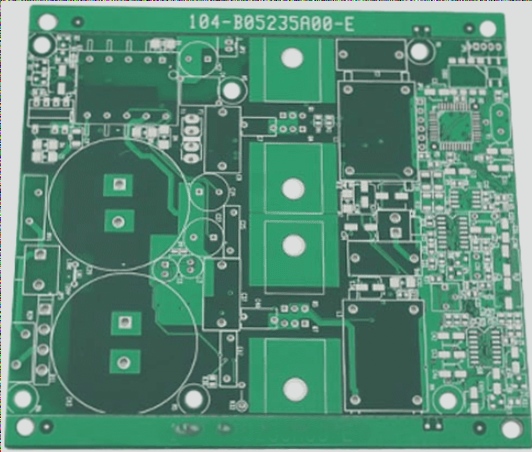

- The automotive electronic PCB processing sector faces high entry barriers due to stringent reliability requirements, resulting in significant profit margins.

Development Prospects of Automotive Electronics PCBA Processing

The growth of autonomous driving and new energy vehicles has driven the demand for automotive printed circuit boards. As the industry shifts towards autonomous and new energy vehicles, the need for automotive PCB control boards continues to rise. This transition is supported by government policies promoting new energy vehicles, leading to widespread utilization of automotive PCB circuit boards. The advancement of technology is expected to enhance the sophistication of automotive intelligent systems.

The increasing use of millimeter-wave radar in vehicles is creating a demand for high-frequency PCB circuit boards. The development of this radar technology is expected to equip a growing number of vehicles in the future, driving the need for high-frequency circuits with stringent requirements on PCB materials and manufacturing processes. Consequently, automotive radar PCBs are poised to offer higher value within the PCBA processing industry.

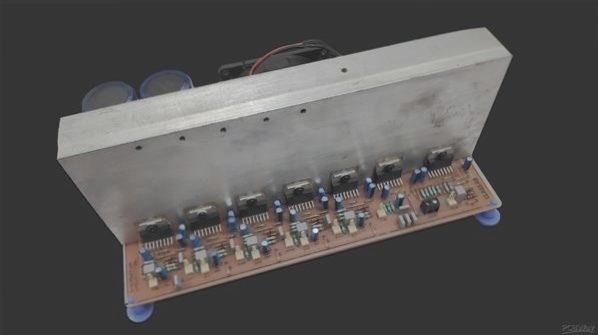

There is significant potential for advancements in new energy vehicle power battery BMS technology. The battery management system (BMS) is crucial for enhancing battery performance and safety. PCB circuit boards, integral to BMS, stand to benefit from innovations in this sector. The market for new energy vehicle PCBs was estimated at 16.4 billion yuan in 2020, reflecting the growth potential in this area.

The automotive printed circuit board processing industry features high entry barriers, with leading manufacturers enjoying advantages in reliability and environmental adaptability. Meeting stringent international standards for zero defects is essential for engaging with major car manufacturers. Once a PCBA manufacturer secures partnerships with these firms, they gain long-term stability and growth opportunities due to the industry’s demanding nature.

The demanding requirements of new energy vehicles underscore the importance of reliable and environmentally adaptable PCB circuit boards, setting high standards for PCBA processing.