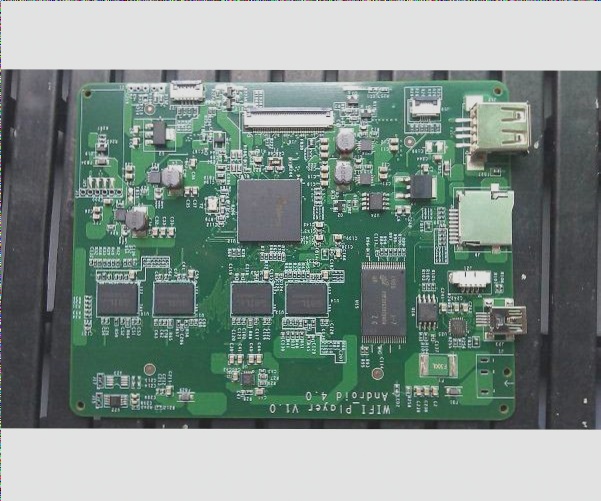

1. In the past, electronic product manufacturers typically completed the entire production of a circuit board by first purchasing the PCB, then contacting a patch manufacturer for processing, and finally transporting it back for assembly, testing, and sales.

2. This was the standard practice, but the entire process was quite cumbersome and resulted in significant time and capital costs.

3. Today, many electronic product manufacturers prefer to work with PCB manufacturers that can handle patch processing simultaneously, or they allow patch manufacturers to take care of PCB procurement.

4. Both approaches greatly reduce hassle and enhance client productivity.

5. The PCBA package, which combines labor and material processing, represents a new method that effectively integrates these two streamlined production techniques.

1. With the advancement of time, social changes have become increasingly frequent, and the electronics industry is undergoing rapid transformations, full of uncertainties. Numerous black swan and gray rhino events have emerged as undeniable realities. In the future, competition among enterprises will intensify, making core competitiveness ever more critical. We have consistently maintained that for companies to achieve breakthroughs moving forward, they must deeply understand their own strengths and requirements, focusing intently on specific breakthrough points instead of dispersing their efforts across the entire value chain. This has nearly become an irreversible trend. Only by letting go can one embrace new opportunities; by relinquishing certain aspects at the right moment, a company can advance further.

2. In light of this, it is essential for all R&D firms and production and sales companies in the electronics sector to carefully assess the total costs associated with raw materials, inventory, personnel management, market opportunities, and more. Following this, comparing the costs of PCB outbound SMT processing with PCBA labor and materials will likely reveal that the PCBA labor and materials model has significantly lowered the overall costs of electronic manufacturing while greatly reducing the risks for the contracting party. Outsourcing professional tasks to specialists may appear to increase individual costs, but in reality, it leads to a marked decrease in overall expenses.

3. Nowadays, the PCB outsourcing SMT processing model is being adopted less frequently by electronic R&D companies. Many are now seeking suitable PCBA contract manufacturers who can provide comprehensive services, allowing them to focus on management roles and personnel coordination for production tracking. Some may express concerns about cash flow, noting that PCBA contract labor and materials typically require around 70% upfront payment, which can be challenging for capital turnover. However, this situation is not vastly different from PCB outsourcing SMT processing, as many upstream materials like ICs and various electronic components are also often purchased outright, with few suppliers offering monthly settlement options.

4. After decades of evolution, the electronics manufacturing industry has matured significantly. The average profit margin in electronic processing has reached saturation, eliminating instances of excessive profiteering. Consequently, electronic processing companies are increasingly competing on quality and service capabilities. The PCBA OEM (contracting labor and materials) processing model effectively supplants the PCB outbound SMT processing approach, reducing overall costs related to personnel, warehousing, procurement, logistics, and after-sales support. This shift has garnered considerable attention from electronic product manufacturers who prioritize core R&D and sales. We have reason to believe that collaboration between electronic product manufacturers and PCBA foundry companies will reach new heights in the future.

2. This was the standard practice, but the entire process was quite cumbersome and resulted in significant time and capital costs.

3. Today, many electronic product manufacturers prefer to work with PCB manufacturers that can handle patch processing simultaneously, or they allow patch manufacturers to take care of PCB procurement.

4. Both approaches greatly reduce hassle and enhance client productivity.

5. The PCBA package, which combines labor and material processing, represents a new method that effectively integrates these two streamlined production techniques.

1. With the advancement of time, social changes have become increasingly frequent, and the electronics industry is undergoing rapid transformations, full of uncertainties. Numerous black swan and gray rhino events have emerged as undeniable realities. In the future, competition among enterprises will intensify, making core competitiveness ever more critical. We have consistently maintained that for companies to achieve breakthroughs moving forward, they must deeply understand their own strengths and requirements, focusing intently on specific breakthrough points instead of dispersing their efforts across the entire value chain. This has nearly become an irreversible trend. Only by letting go can one embrace new opportunities; by relinquishing certain aspects at the right moment, a company can advance further.

2. In light of this, it is essential for all R&D firms and production and sales companies in the electronics sector to carefully assess the total costs associated with raw materials, inventory, personnel management, market opportunities, and more. Following this, comparing the costs of PCB outbound SMT processing with PCBA labor and materials will likely reveal that the PCBA labor and materials model has significantly lowered the overall costs of electronic manufacturing while greatly reducing the risks for the contracting party. Outsourcing professional tasks to specialists may appear to increase individual costs, but in reality, it leads to a marked decrease in overall expenses.

3. Nowadays, the PCB outsourcing SMT processing model is being adopted less frequently by electronic R&D companies. Many are now seeking suitable PCBA contract manufacturers who can provide comprehensive services, allowing them to focus on management roles and personnel coordination for production tracking. Some may express concerns about cash flow, noting that PCBA contract labor and materials typically require around 70% upfront payment, which can be challenging for capital turnover. However, this situation is not vastly different from PCB outsourcing SMT processing, as many upstream materials like ICs and various electronic components are also often purchased outright, with few suppliers offering monthly settlement options.

4. After decades of evolution, the electronics manufacturing industry has matured significantly. The average profit margin in electronic processing has reached saturation, eliminating instances of excessive profiteering. Consequently, electronic processing companies are increasingly competing on quality and service capabilities. The PCBA OEM (contracting labor and materials) processing model effectively supplants the PCB outbound SMT processing approach, reducing overall costs related to personnel, warehousing, procurement, logistics, and after-sales support. This shift has garnered considerable attention from electronic product manufacturers who prioritize core R&D and sales. We have reason to believe that collaboration between electronic product manufacturers and PCBA foundry companies will reach new heights in the future.