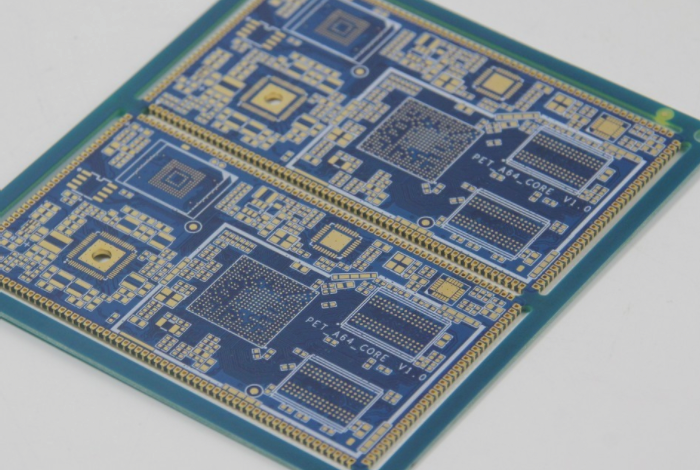

PCBA Processing Techniques and Methods

PCBA, or Printed Circuit Board Assembly, is a crucial step in the manufacturing process where a PCB is populated with components using SMT and DIP techniques.

Surface-Mounted Components in PCBA

- PCBA processing involves SMT surface assembly and DIP packaging, each with specific requirements based on component specifications.

- Surface assembly methods include full surface assembly, single-sided mixed assembly, and double-sided mixed assembly.

Full Surface Assembly Process

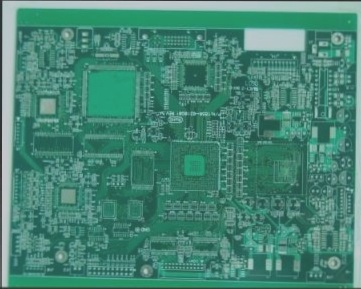

Full surface assembly populates both sides of the PCB with surface-mounted components (SMC/SMD). It can be single-sided or double-sided assembly.

Single-Sided Mixed Packaging

This process combines surface mount components (SMC/SMD) and through-hole components (THC) on one side of the PCB.

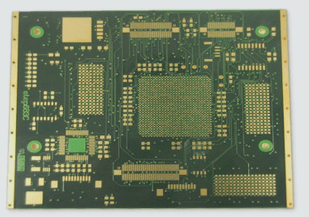

Double-Sided Mixed Installation

Here, SMC/SMD components are placed on both sides of the PCB, with THC on the main side or both sides.

Factors to Consider in PCBA Processing

- Assembly density and SMT line capabilities influence the selection of reflow soldering over wave soldering.

- Advantages of reflow soldering include precise control, lower thermal shock, self-positioning effect, and reduced defects.

- Reflow soldering offers better reliability, monitoring of solder composition, and ease of repair workloads.

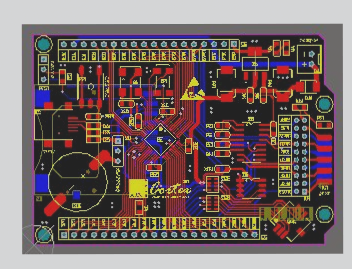

In mixed assembly scenarios, where SMC/SMD and THC are on the same side, reflow soldering on side A and wave soldering on side B is recommended. For THC on side A and SMC/SMD on side B, a glue application and wave soldering process are used for side B.

High-Density Hybrid Assembly Techniques

When dealing with high-density hybrid assembly situations and minimal or no Through-Hole Components (THC), it is common to utilize double-sided solder paste printing and reflow soldering methods. In cases where a small amount of THC is required, it can be added as necessary.

If a significant number of THC components are located on side A of the assembly, the typical processing sequence involves the following steps:

- Printing solder paste on side A

- Reflow soldering

- Applying glue on side B

- Securing components

- Wave soldering

For any additional adjustments or inquiries, please don’t hesitate to reach out!