Preventing False Soldering and Inadequate Soldering in PCBA Processing

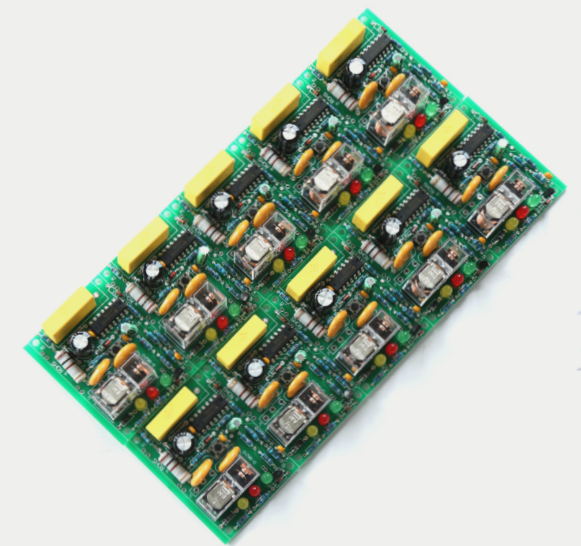

False soldering and inadequate soldering in PCBA processing can lead to quality risks, impact customer satisfaction, tarnish the company’s reputation, reduce production efficiency, and increase costs.

Understanding the Issues

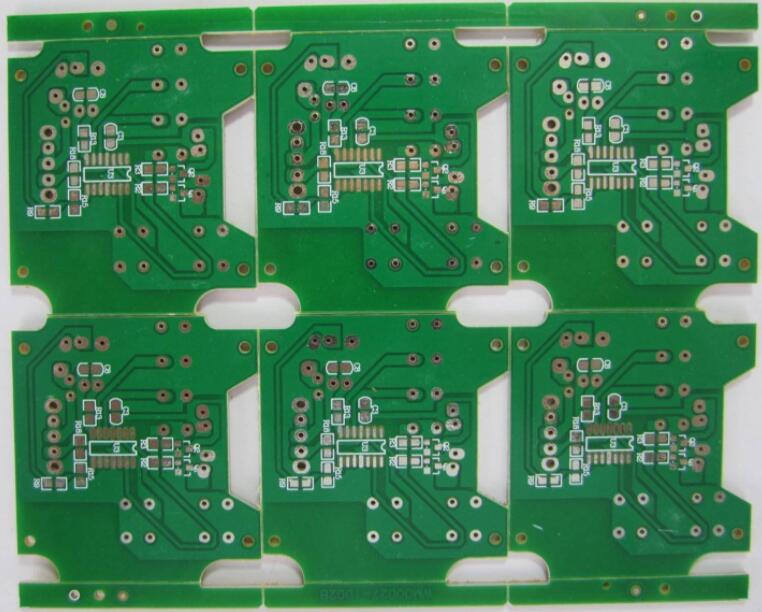

- Inadequate Soldering: This occurs when there is minimal solder adhesion at joints, potentially causing open circuits and poor component contact, reducing the reliability of multilayer PCBs.

- False Soldering: Similar to virtual soldering, false soldering initially allows normal circuit function but may develop into an open circuit over time.

Processes Involved

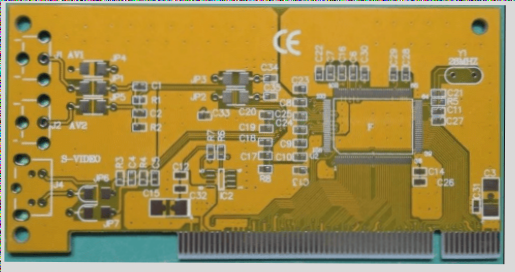

PCB multilayer board soldering, wiring, and debugging are critical processes in PCBA production.

Hazards of False Soldering

False soldering undermines the reliability of PCBs and products, leading to increased maintenance costs, reduced efficiency, quality and safety risks, and higher after-sales expenses.

Preventive Measures

Focus on Soldering Process

- Electric Soldering Iron: Maintain a clean, smooth, and oxide-free tip at the appropriate temperature (300-360 degrees) for optimal soldering results.

- Solder Wire: Use high-quality solder wire (63% tin, 37% lead) in correct amounts to ensure proper wetting of pads and via holes.

- Materials and Tools: Use flux correctly, check welding equipment, and keep tools in good condition to avoid issues.

- Oxidation Check: Remove oxide layers from components before soldering to prevent false soldering.

Adherence to Regulations

Follow process regulations, conduct self-inspection, mutual inspection, and quality checks, and provide essential training to enhance production employees’ skills and awareness.

Quality Control

Intensify inspections, implement a rewards and penalties system, and emphasize employee responsibility and skills development to minimize false soldering incidents.

Conclusion

Employee awareness, responsibility, and skills are key in preventing false soldering. Quality control and a positive service attitude are essential for providing high-quality PCBA processing services to customers.

Ensuring top-notch PCBA processing quality is vital for customer satisfaction and business success.