1. Operation Rules During PCBA Processing

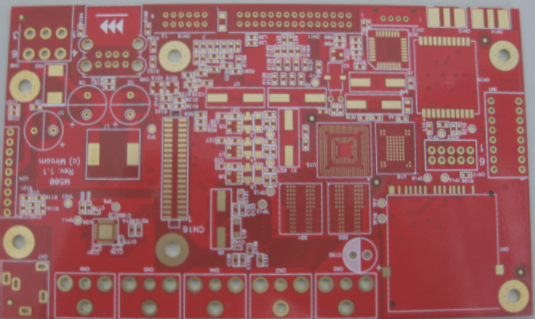

PCBA processing and production involve high-precision manufacturing. It is essential to adhere to the relevant operational specifications during PCBA processing. Improper handling can damage components and PCBA, particularly integrated ICs and other sensitive components. Electrostatic discharge (ESD) protection is crucial, as failure to implement it properly can result in significant damage. Therefore, the production environment and processing technology must meet stringent requirements. Any issues can potentially compromise the entire PCBA or the components on it. So, what are the operating rules during PCBA processing and production? Here are the guidelines from a PCBA processing plant.

1. Maintain a pragmatic, clean, and orderly work environment. Eating and drinking are prohibited in the work area, and smoking is not allowed.

2. Reduce PCBA processing and component operation procedures to minimize risks. If gloves are required on the production line, ensure they are clean; dirty gloves can cause environmental contamination and should be replaced as needed.

3. As a general rule, avoid handling the surface through electric welding with bare hands or fingers, as body oils can diminish weldability.

4. Do not use skin care oils, cleaning agents, or silicone resins together. These substances can interfere with solderability and adhesion in conformal coatings. Use the professionally specified cleaning agents for the welding surface in PCBA processing.

5. Avoid stacking PCBAs to prevent physical damage. Use specialized fixing brackets for the assembly tunneling face.

6. Components and PCBAs sensitive to EOS/ESD must display appropriate EOS/ESD markings. Sensitive PCBA processes should include relevant markings, usually found on the RF connector on the board. To prevent serious damage from ESD and EOS, perform all operations, assembly, and testing on a workbench designed to handle electrostatic discharge.

2. Protective facilities must be established during PCBA processing and production. Static electricity can significantly damage sensitive electronic components, making static protection a systematic project. SMT processing plants must implement and inspect basic anti-static measures, such as grounding wires, floor mats, and anti-static environments.

Once equipment enters the workshop, any non-compliance with regulations will require significant rework. For dedicated long-term product sites, configure anti-static equipment according to specific requirements. For multi-variety production, use the highest level of anti-static equipment.

Protective facilities must be equipped during PCBA processing and production. The anti-static work area should not use wooden floors or materials like wool, hemp, chemical fiber, or ordinary floor leather. Opt for floors made from electrostatic conductive materials, such as anti-static raised floors, and ensure they are properly grounded.

In anti-static areas, use anti-static ceiling materials. Product gypsum board is generally acceptable, while ordinary plastic products are not. Walls should be covered with anti-static wallpaper, and plaster or lime paint is typically allowed; avoid ordinary and plastic wallpaper.

The anti-static devices on the PCBA processing line should be separated from lightning protection lines, with reliable grounding and a complete electrostatic leakage system. Maintain a constant temperature and humidity environment, typically at (25±2) degrees Celsius and 65%±5% relative humidity. Entry points should be equipped with ionized air blowers. An ESD-sensitive symbol with a hand drawn inside indicates the object is highly sensitive to ESD damage.

PCBA processing and production involve high-precision manufacturing. It is essential to adhere to the relevant operational specifications during PCBA processing. Improper handling can damage components and PCBA, particularly integrated ICs and other sensitive components. Electrostatic discharge (ESD) protection is crucial, as failure to implement it properly can result in significant damage. Therefore, the production environment and processing technology must meet stringent requirements. Any issues can potentially compromise the entire PCBA or the components on it. So, what are the operating rules during PCBA processing and production? Here are the guidelines from a PCBA processing plant.

1. Maintain a pragmatic, clean, and orderly work environment. Eating and drinking are prohibited in the work area, and smoking is not allowed.

2. Reduce PCBA processing and component operation procedures to minimize risks. If gloves are required on the production line, ensure they are clean; dirty gloves can cause environmental contamination and should be replaced as needed.

3. As a general rule, avoid handling the surface through electric welding with bare hands or fingers, as body oils can diminish weldability.

4. Do not use skin care oils, cleaning agents, or silicone resins together. These substances can interfere with solderability and adhesion in conformal coatings. Use the professionally specified cleaning agents for the welding surface in PCBA processing.

5. Avoid stacking PCBAs to prevent physical damage. Use specialized fixing brackets for the assembly tunneling face.

6. Components and PCBAs sensitive to EOS/ESD must display appropriate EOS/ESD markings. Sensitive PCBA processes should include relevant markings, usually found on the RF connector on the board. To prevent serious damage from ESD and EOS, perform all operations, assembly, and testing on a workbench designed to handle electrostatic discharge.

2. Protective facilities must be established during PCBA processing and production. Static electricity can significantly damage sensitive electronic components, making static protection a systematic project. SMT processing plants must implement and inspect basic anti-static measures, such as grounding wires, floor mats, and anti-static environments.

Once equipment enters the workshop, any non-compliance with regulations will require significant rework. For dedicated long-term product sites, configure anti-static equipment according to specific requirements. For multi-variety production, use the highest level of anti-static equipment.

Protective facilities must be equipped during PCBA processing and production. The anti-static work area should not use wooden floors or materials like wool, hemp, chemical fiber, or ordinary floor leather. Opt for floors made from electrostatic conductive materials, such as anti-static raised floors, and ensure they are properly grounded.

In anti-static areas, use anti-static ceiling materials. Product gypsum board is generally acceptable, while ordinary plastic products are not. Walls should be covered with anti-static wallpaper, and plaster or lime paint is typically allowed; avoid ordinary and plastic wallpaper.

The anti-static devices on the PCBA processing line should be separated from lightning protection lines, with reliable grounding and a complete electrostatic leakage system. Maintain a constant temperature and humidity environment, typically at (25±2) degrees Celsius and 65%±5% relative humidity. Entry points should be equipped with ionized air blowers. An ESD-sensitive symbol with a hand drawn inside indicates the object is highly sensitive to ESD damage.