The Evolution of Modern Computer Keyboards

- Upon disassembling a traditional computer keyboard, I was amazed by the significant cost reductions in modern keyboard components.

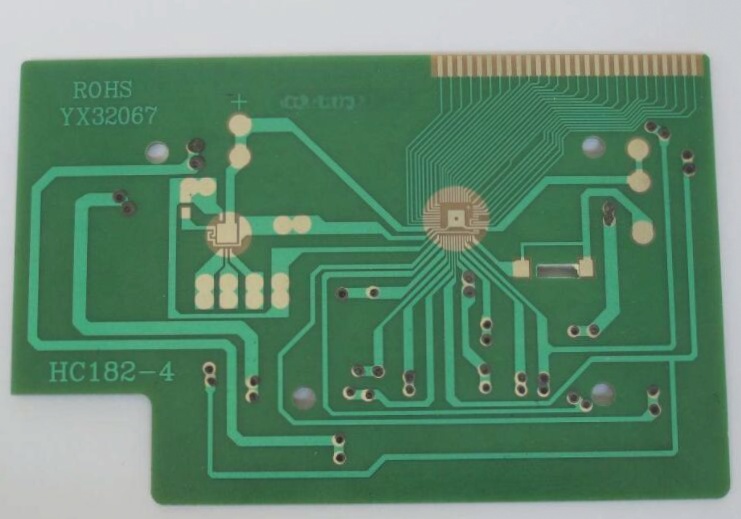

- The circuit board size has been drastically reduced to 5mm x 3mm, featuring a COB and various components including LEDs and capacitors.

- The transition from traditional ICs to COBs and from physical connectors to press-fit connections has led to keyboards costing under US$2.00.

- The remaining components of a modern keyboard include a rubber button membrane, plastic keys, upper and lower keyboard shells, and screws.

When disassembling a keyboard, the circuit board is now only 5mm x 3mm with a COB on the back, handling button processing. The front contains traditional plug-in components like LEDs, capacitors, resistors, and inductors. To enhance quality control, consider converting these components to SMD parts for better PCBA assembly.

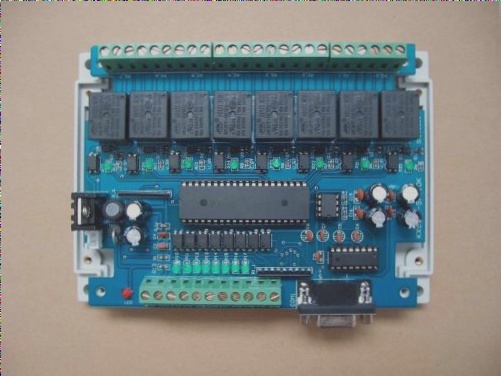

PTF (Polymer Thick Film) technology has replaced traditional PCB button circuits, offering cost savings but lower reliability. Polydome technology is also used for improved performance. Direct press connections, utilizing flexible materials, have replaced connectors and soldering, reducing costs and simplifying assembly.

Key Advancements:

- PTF Technology for Button Circuits

- Press Connection for Cost-Effective Assembly

- Enhanced Quality Control with SMD Components

The innovative use of PTF and press connections in modern keyboards showcases the industry’s commitment to cost efficiency and improved performance.

The Importance of Rubber Membrane in PCB Keyboards

The rubber membrane plays a crucial role in PCB keyboards, sitting between the plastic keyboard and the circuit. Any misalignment can significantly impact key functionality.

Innovative Design Solution

Traditionally, screws were used to secure the membrane in place. However, a new approach has been developed to address the challenges posed by rubber’s expansion and contraction properties. By introducing a larger rubber plunger that can fit into a smaller oval-shaped plastic hole, material and labor costs are reduced.

Enhanced Performance

This innovative design incorporates ingenuity by utilizing an oval-shaped plastic hole to facilitate the insertion of the rubber plunger. This ensures a tight fit, improving the fixing mechanism between the rubber membrane and the plastic. The elliptical hole design optimizes the positioning, enhancing overall performance.