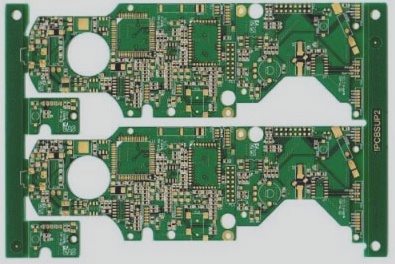

Soldering in PCB Assembly: A Vital Process for Circuit Boards

Soldering is a critical step in the manufacturing and repair of printed circuit boards (PCBs). While automated techniques like Surface Mount Technology (SMT) are prevalent, manual soldering, also known as touch-up soldering, remains indispensable, especially in repair scenarios.

Understanding Soldering

Soldering involves melting a metal alloy, called solder, to join metal surfaces. The molten solder interacts with the metal parts, creating a bond through a chemical reaction, forming an intermetallic compound (IMC) that provides both electrical and mechanical connectivity.

Importance of Soldering

Soldering is crucial for establishing electrical connections between components on a circuit board. It ensures proper communication between components and prevents mechanical failures by securely fixing components to the board.

Significance in Circuit Board Structure

Proper soldering connects component pins to copper foil pads on the PCB, forming electrical pathways that link components and complete the circuit. The quality of soldering directly impacts the reliability and performance of the board.

Experience and Best Practices

- Preheating and Alignment: Align components correctly and preheat the board to prevent thermal shock.

- Solder Quality: Use high-quality solder and flux for reliable joints.

- Avoiding Cold Joints: Ensure sufficient heating to prevent weak electrical connections.

- Cleanliness: Clean the board post-soldering to remove contaminants that can affect performance.

Conclusion

While automated soldering is common, manual soldering skills are crucial for repair work. By following best practices, manufacturers can enhance the quality and reliability of their PCB assemblies.

Manual Soldering Process and Techniques for PCB Assembly

Manual soldering involves using a soldering iron to create reliable electrical connections between component pins and copper pads on the circuit board. The molten solder forms durable joints upon solidification, facilitating electrical signal transmission.

Essential Solder Requirements

- Low Melting Point: Solder should melt at a temperature that does not damage components but remains stable within product operating temperatures.

- Good Electrical Conductivity: Solder must provide reliable electrical connectivity, whether conductive or semi-conductive.

Mechanical Strength in Solder Joints

Ensuring the mechanical strength of solder joints is crucial to withstand impact and vibration. In PCBA (Printed Circuit Board Assembly), tin-based alloys are commonly used due to their strength and durability.

Alloy Composition and Benefits

Alloying tin with metals like silver and copper improves solder joint strength and durability. Silver enhances wetting ability, while copper reduces corrosion on soldering iron tips.

Soldering Principle

The soldering process involves melting solder to connect component leads to the circuit board. Proper heating with an electric soldering iron ensures a reliable bond between components.

Key Considerations in Manual Soldering

- Efficient Heating: Avoid overheating components by heating joints quickly at low temperatures.

- Heat Capacity: Use a soldering iron with sufficient wattage for proper thermal compensation.

- Tip Selection: Choose the right tip size for efficient heat transfer, especially for large pads.

Indicators of a Good Solder Joint

- Smooth and even solder flow around component leads and pads.

- Natural, shiny appearance with full coverage of component leads.

Manual Soldering Best Practices

- Heating the Joint: Heat pads and pins before applying solder for efficient bonding.

- Applying Solder: Feed enough solder to ensure proper wetting of pads and leads.

- Soldering Large Joints: Move the iron to evenly cover large joints with solder.

- Minimizing Heat Exposure: Avoid prolonged heating to prevent component damage.

- Removing the Iron: Quickly remove the iron after soldering to form clean joints.

Mastering Manual Soldering for High-Quality PCB Assembly

Manual soldering is a meticulous and exacting process that demands precision in temperature control, timing, and technique to produce top-notch solder joints. By grasping the characteristics of solder and adhering to recommended procedures for heating, applying solder, and preventing overheating, technicians can attain dependable and long-lasting connections in printed circuit board assembly (PCBA).

For the latest tips and tricks on PCB assembly, don’t hesitate to contact me at info@wellcircuits.com.