Introduction to PCBA Technology: Understanding Moisture Sensitive Devices

Moisture Sensitive Devices (MSDs) are electronic components that are highly sensitive to moisture levels in their environment. When we talk about “moisture,” we are referring to the presence of water vapor in the air surrounding these components, not liquid or solid water. It’s crucial to understand that humidity, not visible water, can impact these devices.

How Moisture Affects Electronic Components

Water vapor molecules are smaller than those of liquid water, allowing them to penetrate tiny gaps in moisture-sensitive devices. When exposed to heat, such as in a reflow oven, the trapped moisture can expand rapidly, creating pressure that can lead to various issues within the components.

Control Moisture Levels for Component Safety

Controlling moisture levels is essential to prevent damage to electronic components. Industrial standards like IPC provide guidelines for handling moisture-sensitive devices and define Moisture Sensitive Levels to ensure proper care during manufacturing and storage.

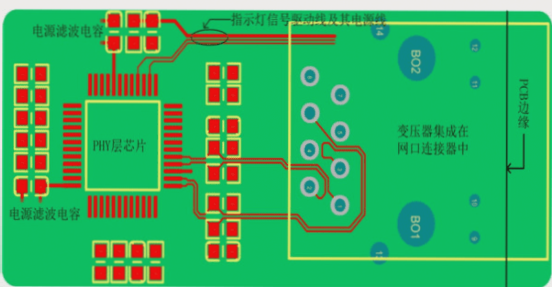

Identifying Components at Risk

Components with small gaps, like ICs (Integrated Circuits), are particularly vulnerable to moisture damage. The enclosed nature of IC packaging can trap moisture, leading to delamination, cracking, or other issues during reflow processes.

Industry Standards for Moisture-Sensitive Components

The PCB industry has specific standards to classify and handle moisture-sensitive parts, focusing on preventing delamination and other effects caused by moisture. These standards help manufacturers evaluate component sensitivity levels and establish proper handling procedures to maintain component reliability post-reflow soldering.

Understanding Moisture-Sensitive Parts in PCBs

After learning about “moisture-sensitive parts,” you may be curious about why various components, not just ICs, often need vacuum drying packaging to control humidity. Moisture can cause delamination due to thermal expansion and accelerate the oxidation of metal coatings on component leads, leading to issues like solder rejection. Some plastic materials, such as PA (nylon), can also absorb moisture, causing problems like embrittlement, deformation, and discoloration under high temperatures.

Custom Moisture-Proof Solutions for Electronic Components

Because electronic components lack uniform humidity control conditions, a one-size-fits-all standard is not feasible. Instead, moisture-proof requirements must be tailored to each component. In addition to IC-related risks, other parts face potential explosion and delamination issues, which can vary from one component to another.