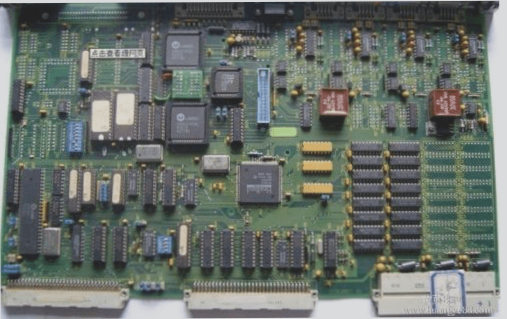

1. Making a PCB board is not a straightforward task; it’s more than just drilling holes and inserting components. While PCB production itself isn’t overly complex, the real challenge arises during troubleshooting after the board is completed. Whether for a personal project or in an industrial setting, encountering issues during PCBA debugging can be quite frustrating—much like a programmer facing bugs in their code.

2. Some individuals have a keen interest in debugging PCBA circuit boards. Similar to how programmers tackle bugs, there are several common issues associated with PCBA circuit boards. Common problems include circuit board design flaws, damaged electronic components, short circuits, and faulty connections. Disconnection faults in PCBA circuit boards are not uncommon.

3. The majority of PCBA circuit board failures are concentrated in components such as capacitors, resistors, inductors, diodes, transistors, and field-effect transistors. Integrated chips and crystal oscillators can also show signs of damage. A practical method for identifying failures in these components is through visual inspection. Obvious burn marks on the surface of damaged electronic components are telltale signs. Such failures can typically be resolved by replacing the faulty components with new ones.

—

Let me know if you need any further adjustments!

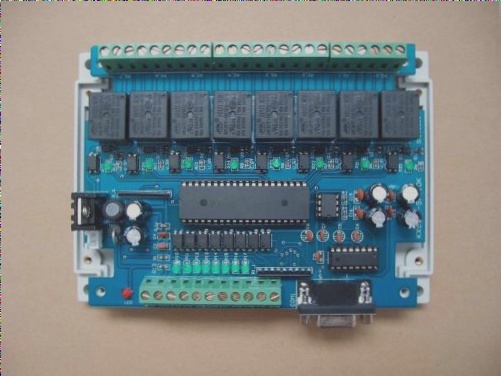

1. Of course, not all electronic component damage is visible to the naked eye, such as resistors, capacitors, diodes, and others. In some instances, damage may not be apparent from the surface, necessitating the use of professional inspection tools for repair. Common inspection methods include multimeters and capacitance meters. If the voltage or current of a specific electronic component is detected to be outside the normal range, it indicates a potential issue with that component or a preceding one. In such cases, direct replacement and subsequent checks are advisable to verify normal operation.

2. Component failure can often be detected visually or through instruments; however, there are instances where problems arise on a PCB that are not easily identified, resulting in malfunctioning circuit boards. Many novices encounter such issues and may resort to creating a new board or purchasing one. In reality, this situation often stems from the unstable performance of components due to their interdependent operation during installation.

3. When this occurs, instruments may prove unhelpful. One can attempt to narrow down the fault range based on current and voltage readings. An experienced engineer may quickly identify the fault area, but pinpointing the exact faulty component is rarely guaranteed. The only viable solution is to replace the suspected components incrementally until the defective one is located. Last year, my laptop motherboard was water-damaged, and during repairs, the technician encountered undetectable faults. Throughout the process, I replaced three components: the power supply chip, diode, and USB charging component (the blue notebook connector). Ultimately, after extensive testing and investigation, we identified a short circuit in a component adjacent to the South Bridge chip.

4. This scenario illustrates a common issue with electronic components. Given that the PCBA circuit board serves as the foundation for these components, circuit board failures are inevitable. A straightforward example is a dead tinned area. Due to manufacturing processes, PCB corrosion may lead to disconnections. In such cases, if re-wiring isn’t feasible, using thin copper wire for a flying lead can provide a solution.

5. Dealing with PCBA circuit board failures can be quite challenging when damage is not overtly visible. Troubleshooting demands focused attention, and discovering the root problem often brings an inexplicable sense of accomplishment, akin to a programmer resolving a bug. In this spirit, I enjoy investigating particularly challenging boards; it’s a pursuit I find quite rewarding.