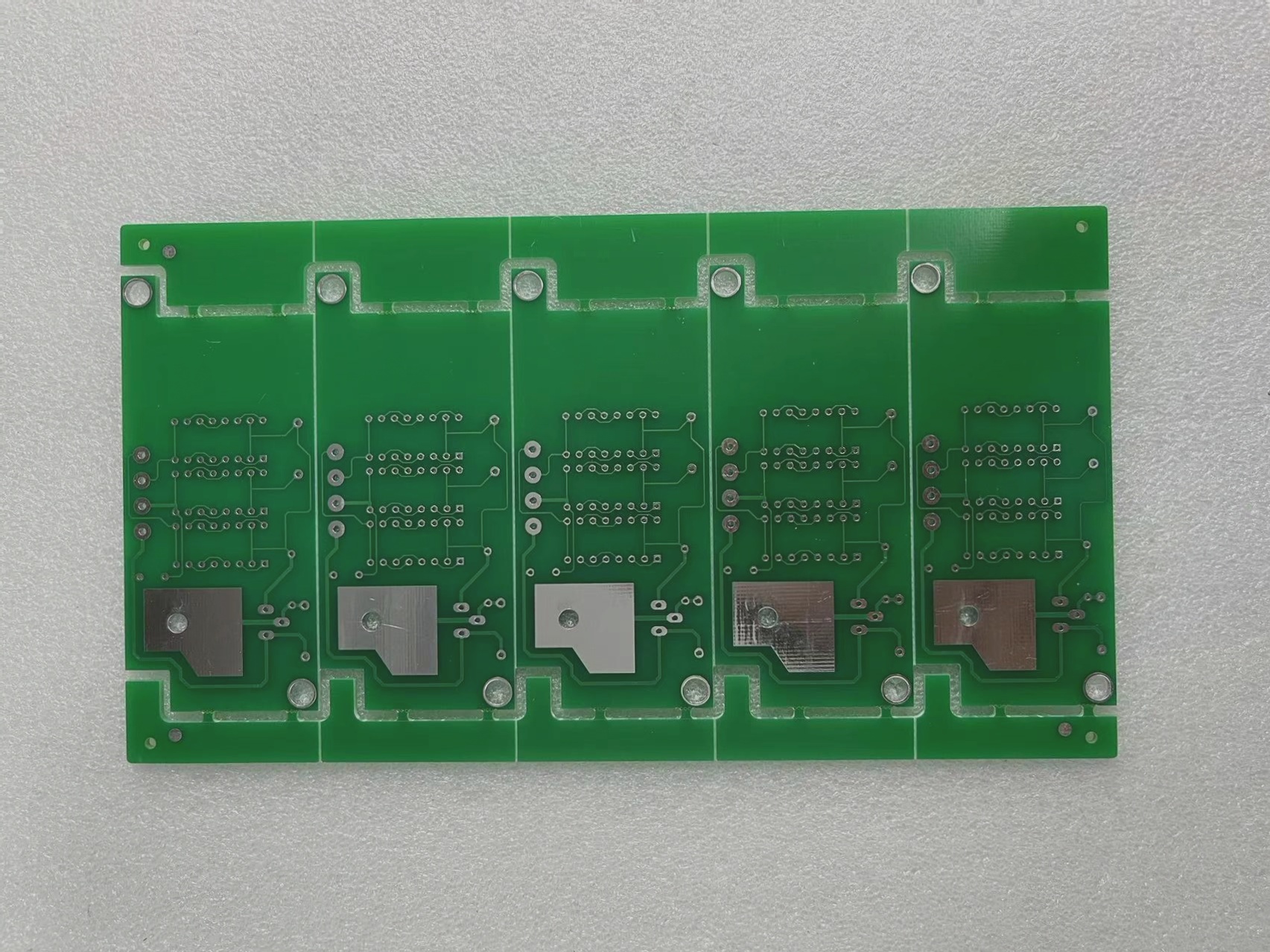

Surface Mount Technology (SMT) Revolutionizing PCB Assembly

- SMT, or Surface Mount Technology, is a cutting-edge electronic assembly technique that has transformed the industry.

- PCBs are essential for electronic devices, providing a platform for integrated circuits and components.

- Historically, SMT has evolved from older methods like flush mount and hybrid mounting to become the industry standard.

The Evolution of SMT

In the 1950s, SMT began with flat-mounted elements for military applications and has since advanced through hybrid technology to dominate the market today.

Advantages of SMT

- SMT offers size, weight, and automated production advantages over traditional through-hole methods.

- Surface-mounted devices (SMDs) in SMT enable compact designs and cost-effective production.

- Automated assembly in SMT enhances manufacturing efficiency, particularly for mass production.

Benefits of SMT Construction

- High assembly density and reduced weight due to smaller SMD components.

- Significant volume and weight reductions in electronic products after transitioning to SMT.

- Enhanced reliability, vibration resistance, and reduced interference in SMT products.

Efficiency and Cost Savings

By eliminating through-hole components, SMT simplifies assembly, reduces production time, and enhances quality. Automation further improves efficiency and cuts costs significantly.

Quality PCBA Services

Explore our PCBA services to experience the reliability and efficiency of Surface Mount Technology.

Benefits of SMT Assembly in PCB Manufacturing

When it comes to PCB manufacturing, precision is key. Machining with drilled through-holes requires exact alignment, often needing customization to suit specific PCB layouts and component placements. However, Surface Mount Technology (SMT) assembly has revolutionized the industry by largely eliminating the need for through-hole components.

By transitioning to SMT assembly, manufacturers can enjoy a host of benefits. Firstly, it enables greater automation in the assembly process, leading to increased efficiency and cost reduction. Additionally, SMT assembly minimizes the use of Surface Mount Device (SMD) small leads, or in some cases, eliminates them entirely.

Overall, the adoption of SMT assembly in PCB manufacturing streamlines processes, enhances precision, and ultimately results in higher quality end products. Embracing this technology can propel manufacturers towards greater competitiveness in the market.