PCB play an indispensable role in a wide range of applications, including the highly important field of metering technology. Meters are essential tools used for measuring various parameters like electricity consumption, water flow, gas usage, and more. Now let’s see the pivotal role PCB play in meter projects.

1. Smart Metering Systems:

In today’s world, the demand for smart metering systems is on the rise. These systems, which are integral in monitoring and managing utility consumption, rely heavily on advanced PCBs. Smart meters, both residential and industrial, use complex PCBs to process data, communicate with central servers, and provide users with real-time consumption information. These boards enable the seamless integration of wireless communication modules (like Wi-Fi, Zigbee, or LoRa) and advanced microcontrollers to ensure accurate data collection and transmission.

2. Energy Meters:

Electricity meters, used in residential and industrial settings, are another key application for PCBs. These meters need precision PCBs to measure energy consumption accurately. Multilayer PCBs allow for compact designs, enabling manufacturers to create smaller, more cost-effective meters. In addition, PCBs in energy meters include components like current transformers, which require careful PCB layout to ensure precise measurement and calibration.

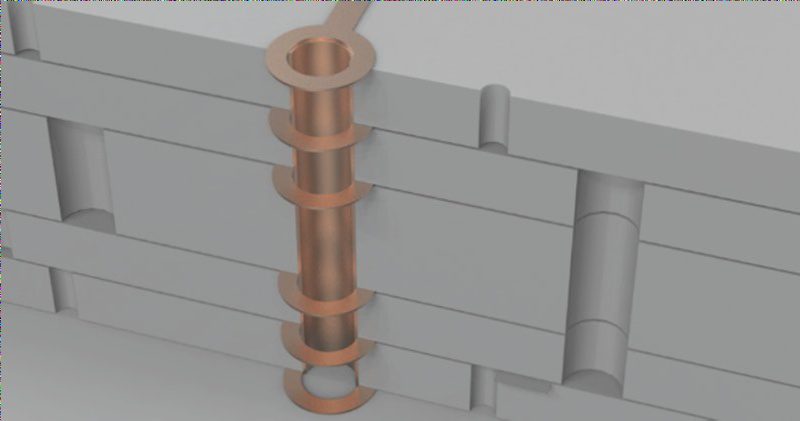

3. Water and Gas Meters:

Water and gas meters are crucial for tracking usage and billing. PCBs in these meters are designed to withstand environmental challenges, such as exposure to moisture and temperature fluctuations. PCBs facilitate the integration of sensors that measure the flow rates of water and gas and convert this data into consumption information. Additionally, they play a role in wireless communication with remote servers for data reporting.

4. Flow Meters:

Flow meters, used in various industries like manufacturing and agriculture, rely on PCBs for data processing and output. These meters use specialized sensors, often integrated with PCBs, to measure the rate of fluid or gas flow. The PCBs in flow meters facilitate data processing, display, and connectivity to other systems for process control and monitoring.

5. Calibration Equipment:

PCBs are essential in the manufacturing of calibration equipment for meters. Calibration ensures the accuracy of meter readings over time. PCBs in calibration equipment contain precise voltage and current sources to calibrate the meters accurately.

6. Remote Monitoring and Data Logging:

PCBs enable the incorporation of remote monitoring and data logging capabilities in meters. This feature is critical in applications where continuous data collection is needed, such as in industrial settings or research projects. PCBs help store and transmit data efficiently.

7. Environmental Monitoring:

Some meters are designed for environmental monitoring, such as air quality, temperature, or humidity measurement. PCBs in these meters enable the integration of various sensors and communication modules to collect data for research and decision-making.

In summary, PCBs are the unsung heroes of metering technology. They facilitate accurate data collection, data processing, and communication, ensuring that utility consumption is measured reliably. In an era of increasing demand for accurate and efficient measurement, PCBs in meter projects are at the forefront of technological advancements, contributing to improved resource management and sustainability.

In our company , we make 2 layers and 4 layers rigid PCBs for meter projects.