Optimizing PCB Wiring in Protel DXP: Manual Adjustments Guide

Enhancing Automatic Routing with Manual Tweaks

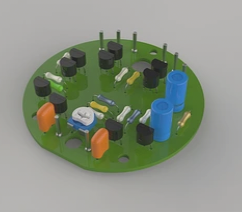

When working with PCB automatic wiring in Protel DXP, manual adjustments play a crucial role in overcoming the limitations of automatic routing. While automatic routing may result in excessive turns and corners, manual tweaking can significantly improve the layout and efficiency of the wiring.

Identifying and Addressing Wiring Issues

- Excessive Turns: Automatic routing in Protel DXP often leads to wiring with too many corners, affecting both aesthetics and functionality.

- Efficient Adjustments: Manual modifications can enhance wiring by considering spatial relationships between wires and optimizing the overall layout.

For example, in the Mypcb.PCBDoc file, we can identify areas where wiring adjustments are needed. By focusing on specific networks like the -12 network, we can isolate problematic sections and make targeted improvements.

Improving Wiring Efficiency

By repositioning vias and optimizing wire paths, we can create a more direct and streamlined connection between components. This not only improves the functionality of the PCB but also enhances its visual appeal.

Optimizing Wiring Density

Manual adjustments are essential for optimizing wiring density across the PCB. By redistributing wires from high-density areas to less populated regions, we can achieve a more balanced layout and efficient use of space.

Resolving Wiring Challenges

In cases where wires obstruct the routing of adjacent connections, manual repositioning is necessary to ensure smooth signal flow. By addressing wiring issues promptly, we can create a well-organized and effective PCB layout.

Manual Adjustments in Protel DXP for Optimal PCB Routing

- Minimizing Excessive Vias

- Implementing Anti-Interference Wiring Principles

- Removing Fill Areas and Auxiliary Wiring

Protel DXP tends to use too many vias during routing, but you can reduce their number manually. Start by eliminating networks that share the same direction and those in different directions. Then, route the networks in the same direction first, followed by the opposite direction. This method can significantly cut down on the total number of vias.

PCB wiring goes beyond mere connections; anti-interference measures are crucial. Factors like crosstalk and impedance control must be taken into account. Crosstalk from adjacent signal lines can cause interference and affect signal impedance. Analyzing the coupling of parallel signal lines helps determine safe distances between them and the lengths of parallel runs.

After finishing all PCB wiring, delete the fill areas in Protel DXP to allow for automatic routing within designated fill zones. Simply use the Delete command from the Edit menu or select the fill area and press the [Delete] key on your keyboard to remove them.