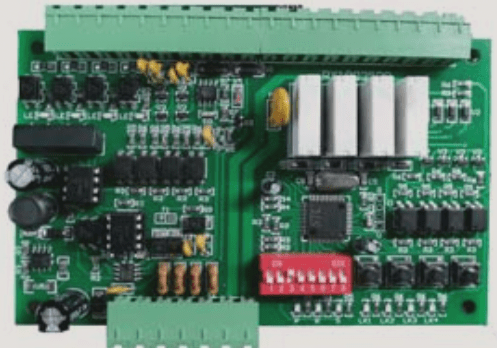

In recent years, the market has experienced rapid growth, leading to improvements across various aspects of life. Circuit boards are primarily utilized for the mass production of fixed circuits and the optimization of electronic devices. So, are you aware of the performance characteristics of circuit boards? How is their working principle established? Let’s delve into “the performance advantages and operating methods of circuit boards.”

[How PCB Ultrapure Water Equipment Functions and Its Benefits]

PCB ultrapure water equipment employs a traditional water treatment method in which various anions and cations in water are exchanged using anion and cation exchange resins. These resins can be combined in different ratios to create an ion exchange cation bed system, an anion bed system, and a mixed-bed (multi-bed) system. The mixed-bed system is typically utilized following reverse osmosis and other water treatment processes to produce ultrapure water.

The final step in producing high-purity water remains an indispensable method for generating both ultrapure and high-purity water.

# Working Principle of Circuit Board Ultrapure Water Equipment

The circuit board ultrapure water equipment processes water through a cation exchange resin, typically a styrene-based strong acid cation exchange resin. The cations present in the water are absorbed by the resin, while the cation H+ on the resin is released into the water, forming a corresponding inorganic acid. This acidic water is then passed through an anion exchange resin, usually a styrene-based strong basic anion resin, where OH- combines with the H+ in the water to produce ionized water.

Deionized water finds extensive applications across modern industries. Its use is crucial for many sectors in China striving to enhance product quality and align with global standards.

The electrical conductivity of the circuit board ultrapure water equipment can be below 1 µS/cm, while the electrical resistivity of the effluent can exceed 1 MΩ·cm. Depending on the water quality and application needs, the effluent’s electrical resistivity can be maintained between 1 and 18 MΩ·cm. This equipment is widely utilized for the preparation of industrial ultrapure water and high-purity water in sectors such as electronics, power generation, chemicals, electroplating, boiler makeup, and pharmaceuticals.

# Advantages of Ultrapure Water Equipment for Circuit Boards

Ultrapure water equipment for circuit boards allows for precise control over the ion concentration in deionized water, enabling effective management of resistivity, solubility, corrosivity, as well as the presence of viruses and bacteria, along with other physical, chemical, and pathological parameters.

In both production and laboratory settings within the electronics industry, employing ultrapure water equipment can align various parameters with design specifications or ideal conditions, thereby simplifying the quality control of PCB products.

# Usage Requirements and Equipment Characteristics of Circuit Board Ultrapure Water Equipment

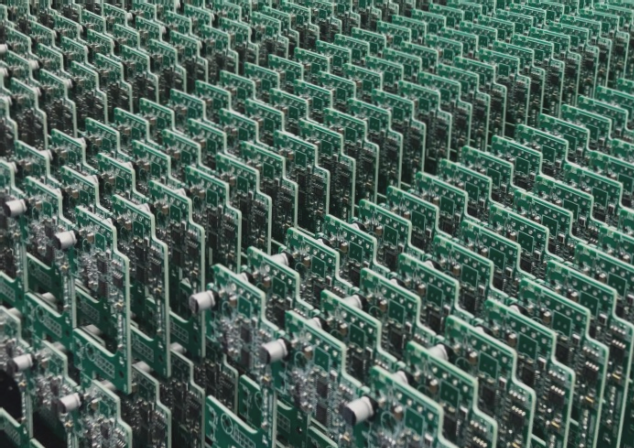

Circuit board ultrapure water equipment is primarily employed in the production of aluminum foil for electrolytic capacitors, as well as for cleaning components. It is also utilized in manufacturing electron tubes, kinescopes, and cathode ray tubes, including black-and-white kinescopes and fluorescent screens. The equipment incorporates advanced pure water production technology to ensure the water’s purity meets user requirements for production processes.

1. Pure water quality standards for picture tubes and liquid crystal displays (empirical data).

2. Pure water quality standards for integrated circuits.

3. National standards for electronic-grade pure water.

4. American SEMI standards.

# Features of PCB Ultrapure Water Equipment

To meet user requirements, achieve compliant water quality, minimize pollution at every level, prolong equipment lifespan, and reduce operator maintenance workload, the design process uses water that meets national tap water standards as the source. It is then equipped with a media filter, activated carbon filter, sodium ion softener, precision filter, and other pretreatment systems, as well as a reverse osmosis (RO) system and an ion exchange mixed bed (EDI electric desalination system).

In the circuit board ultrapure water equipment system, the water tank includes a liquid level control system, the water pump features a pressure protection device, and there is an online water quality detection instrument. The system is operated using a PLC programmable controller, facilitating unattended operation. Furthermore, the materials selected during the process are aligned with both standardized recommendations and customer requirements, ensuring enhanced cost efficiency and reliability compared to other similar products.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me

[How PCB Ultrapure Water Equipment Functions and Its Benefits]

PCB ultrapure water equipment employs a traditional water treatment method in which various anions and cations in water are exchanged using anion and cation exchange resins. These resins can be combined in different ratios to create an ion exchange cation bed system, an anion bed system, and a mixed-bed (multi-bed) system. The mixed-bed system is typically utilized following reverse osmosis and other water treatment processes to produce ultrapure water.

The final step in producing high-purity water remains an indispensable method for generating both ultrapure and high-purity water.

# Working Principle of Circuit Board Ultrapure Water Equipment

The circuit board ultrapure water equipment processes water through a cation exchange resin, typically a styrene-based strong acid cation exchange resin. The cations present in the water are absorbed by the resin, while the cation H+ on the resin is released into the water, forming a corresponding inorganic acid. This acidic water is then passed through an anion exchange resin, usually a styrene-based strong basic anion resin, where OH- combines with the H+ in the water to produce ionized water.

Deionized water finds extensive applications across modern industries. Its use is crucial for many sectors in China striving to enhance product quality and align with global standards.

The electrical conductivity of the circuit board ultrapure water equipment can be below 1 µS/cm, while the electrical resistivity of the effluent can exceed 1 MΩ·cm. Depending on the water quality and application needs, the effluent’s electrical resistivity can be maintained between 1 and 18 MΩ·cm. This equipment is widely utilized for the preparation of industrial ultrapure water and high-purity water in sectors such as electronics, power generation, chemicals, electroplating, boiler makeup, and pharmaceuticals.

# Advantages of Ultrapure Water Equipment for Circuit Boards

Ultrapure water equipment for circuit boards allows for precise control over the ion concentration in deionized water, enabling effective management of resistivity, solubility, corrosivity, as well as the presence of viruses and bacteria, along with other physical, chemical, and pathological parameters.

In both production and laboratory settings within the electronics industry, employing ultrapure water equipment can align various parameters with design specifications or ideal conditions, thereby simplifying the quality control of PCB products.

# Usage Requirements and Equipment Characteristics of Circuit Board Ultrapure Water Equipment

Circuit board ultrapure water equipment is primarily employed in the production of aluminum foil for electrolytic capacitors, as well as for cleaning components. It is also utilized in manufacturing electron tubes, kinescopes, and cathode ray tubes, including black-and-white kinescopes and fluorescent screens. The equipment incorporates advanced pure water production technology to ensure the water’s purity meets user requirements for production processes.

1. Pure water quality standards for picture tubes and liquid crystal displays (empirical data).

2. Pure water quality standards for integrated circuits.

3. National standards for electronic-grade pure water.

4. American SEMI standards.

# Features of PCB Ultrapure Water Equipment

To meet user requirements, achieve compliant water quality, minimize pollution at every level, prolong equipment lifespan, and reduce operator maintenance workload, the design process uses water that meets national tap water standards as the source. It is then equipped with a media filter, activated carbon filter, sodium ion softener, precision filter, and other pretreatment systems, as well as a reverse osmosis (RO) system and an ion exchange mixed bed (EDI electric desalination system).

In the circuit board ultrapure water equipment system, the water tank includes a liquid level control system, the water pump features a pressure protection device, and there is an online water quality detection instrument. The system is operated using a PLC programmable controller, facilitating unattended operation. Furthermore, the materials selected during the process are aligned with both standardized recommendations and customer requirements, ensuring enhanced cost efficiency and reliability compared to other similar products.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me