**PCB Performance Characteristics**

1. **Film and Sheet Applications:** Various non-toxic and sterile packaging materials for food, pharmaceuticals;

Packaging materials for textiles, precision instruments, and electrical components;

Base materials for audio tapes, video tapes, motion picture films, computer floppy disks, metal coatings, and photosensitive films;

Electrical insulation materials, capacitor films, flexible printed circuit boards, membrane switches, and other electronic and mechanical applications.

2. **Bottle Packaging Applications:** The use of packaging bottles has evolved from initial carbonated beverages to include a wide range of products such as beer bottles, edible oil containers, condiment bottles, medicine bottles, cosmetic containers, and more.

3. **Electronic Appliances**: Manufacturing components such as connectors, coil bobbins, integrated circuit housings, capacitor enclosures, transformer casings, TV accessories, tuners, switches, timer housings, automatic fuses, motor brackets, and relays, among others.

4. **Auto Parts**: Components like switchboard covers, ignition coils, various valves, exhaust systems, distributor covers, instrument enclosures, and small motor casings can also be produced using PET’s superior coating properties, surface finish, and rigidity for external automotive parts.

5. **Mechanical Equipment**: The production of gears, cams, pump housings, pulleys, motor frames, and watch components is achievable, along with applications as microwave oven bakeware, various ceilings, outdoor billboards, and models.

6. **Molding Processes for PET Plastics**: PET can be processed through various methods, including injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, vacuum metal plating, and printing.

**PCB Performance Specification**

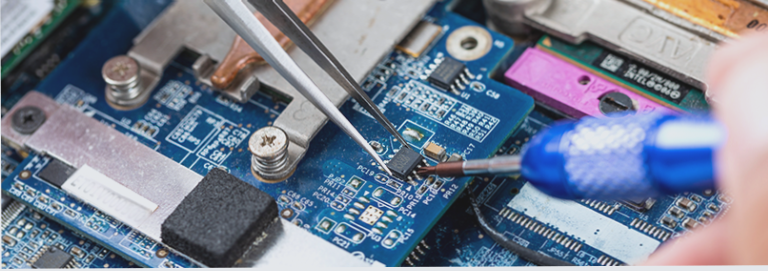

1. **Printed Circuit Board**

A printed circuit board (PCB), commonly referred to as a bare PCB, is typically categorized based on the number of layers it possesses: single-sided, double-sided, or multilayer. Additionally, it can be classified by structure into flexible printed circuit boards, rigid printed circuit boards, and rigid-flex printed circuit boards. The PCB serves as the foundation for circuit interconnections and the assembly of printed circuit board assemblies (PCBA), which sometimes refers to the circuit board that includes components.

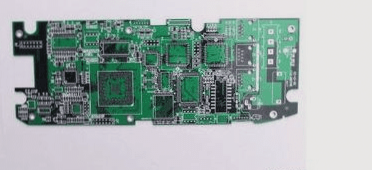

2. **Structure of Rigid Multilayer PCB**

A rigid multilayer PCB consists of multiple circuits and insulating layers, with interlayer connections achieved through electroplated vias.

3. **PCB Manufacturability Design**

The manufacturability design of PCBs primarily addresses the processability challenges. Its goal is to ensure that the designed PCB can be manufactured efficiently in one go while meeting the assembly and usage requirements. This design is influenced by factors such as narrow line widths/spacing, small pad ring widths, and minimal solder mask bridge widths, aligned with the processing capabilities of the PCB manufacturing facility. A thorough understanding of PCB production methods, principles, and characteristics is essential for mastering economical and advanced processing capabilities.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me