The Importance of Test Points in PCB Testing

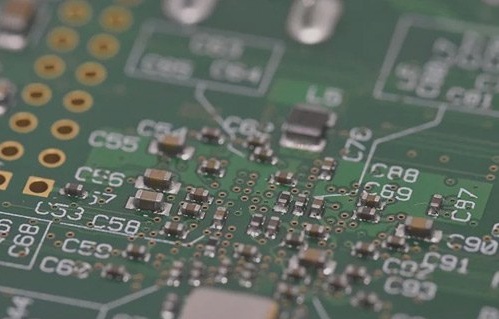

Test points play a crucial role in ensuring that electronic components on a PCB meet specifications and solderability standards. In mass production facilities, manually testing every component is impractical, leading to the use of ICT automated testing machines equipped with “Bed-Of-Nails” fixtures.

- ICT machines make simultaneous contact with all components on the board for efficient testing.

- Test points, small round dots without a solder mask, provide additional connections at component ends to prevent damage during testing.

- With the shift from through-hole to surface mount technology, test points have become essential due to poor probe contact caused by solder paste residues.

- Test points enhance test reliability by avoiding direct pressure on delicate SMT components, reducing the risk of damage and ensuring accurate measurements.

Enhancing PCB Testing Efficiency

Test points are a critical aspect of PCB testing, ensuring the reliability and accuracy of measurements while safeguarding electronic components from potential damage. By utilizing test points and automated testing methods, manufacturers can streamline the testing process and maintain high-quality standards in electronic production.