The Process Principle of PCB Resin Plug Hole Grinding Production

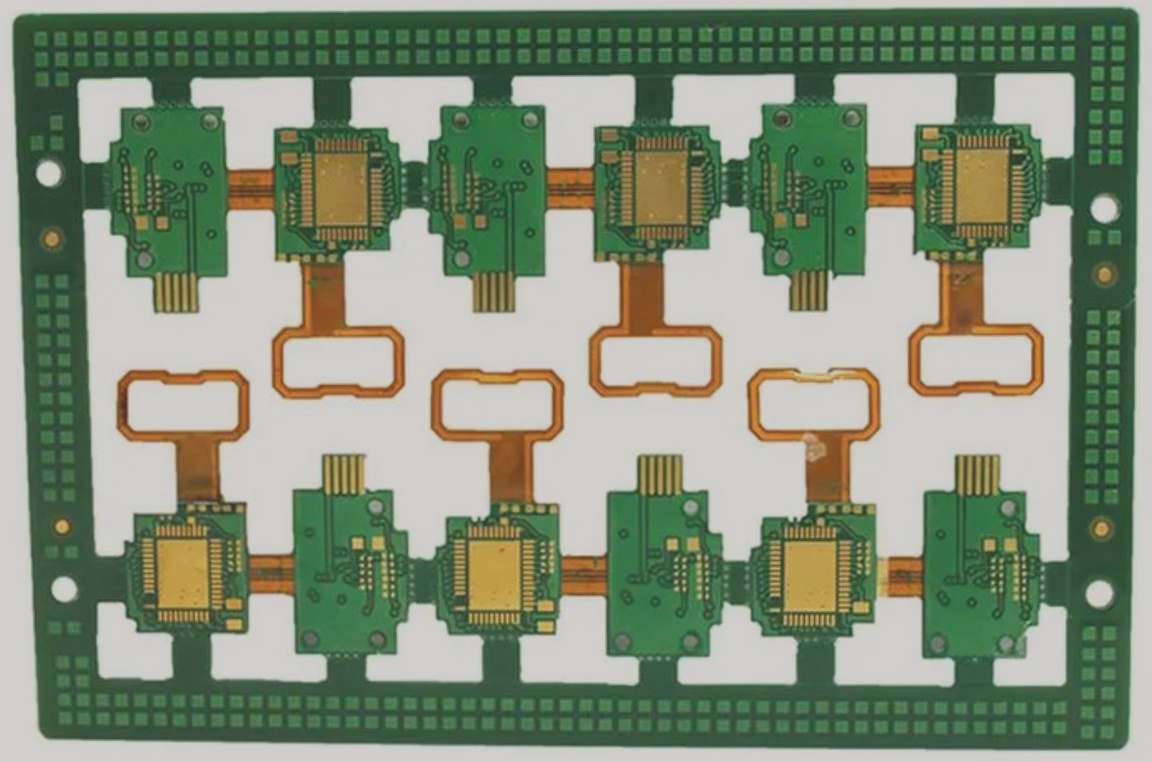

The production process of printed circuit board (PCB) resin plug hole grinding involves using special plug hole ink to cure the hole, followed by polishing to remove excess ink above the copper surface. Wet film production then proceeds according to the standard process flow for non-plug hole boards. Resin plug holes are typically finalized after a single copper electroplating. The sequence of the grinding production process is as follows: grinding plate → plug hole → curing → grinding.

Quality Control and Equipment in Inner Plug Hole Grinding

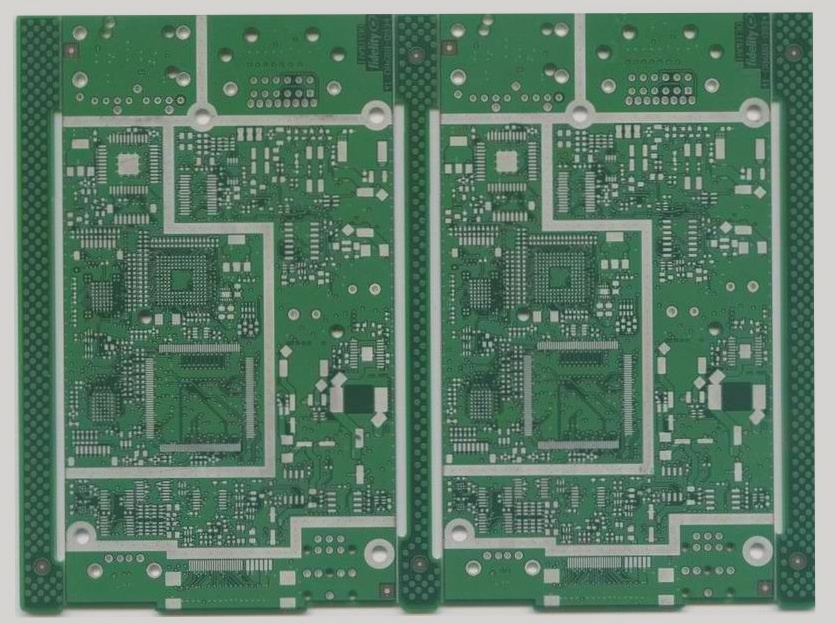

Ensuring the quality of inner plug hole grinding and preventing irregularities requires addressing various factors such as hole depression, corner damage, plate expansion and contraction, grinding roughness, grinding amount, grinding cost, thin plate capability, and grinding wheel compatibility. Strict control of these characteristics is essential to enhance overall process yield. Automatic pressure-regulating grinding machines are commonly used equipment in PCB plug hole grinding.

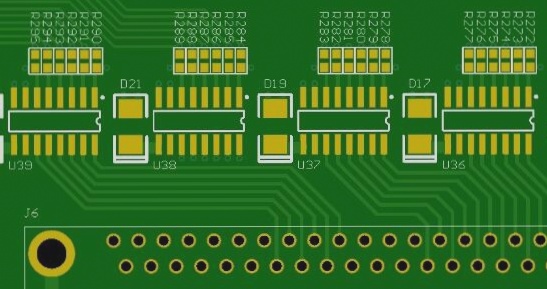

Types of Grinding Wheels and Selection Considerations

Automatic pressure-regulating grinders utilize ceramic and non-woven grinding wheels. Ceramic wheels offer superior cutting ability without leaving surface dents post-grinding, albeit at a higher cost and shorter service life. Non-woven grinding wheels also provide excellent cutting ability but may leave holes due to structural factors. While cost-effective, their price is significantly lower than ceramic wheels. Choosing the most suitable grinding wheel combination based on individual plug hole characteristics is advisable.

Control of PCB Expansion and Contraction

For effective control of printed circuit board expansion and contraction, utilizing four-axis grinding for testing is recommended. Rotating the inner layer board by 90° before four-axis grinding allows for optimal control of grinding roughness and expansion/contraction. This approach also helps disperse damage to the plug hole, preventing concentration in a single direction.