**How to Design the Power Loop in a PCB Circuit Board**

I have several years of experience in power board layout and have summarized some key considerations. The following points highlight the main areas of concern when designing the power loop in a PCB:

1. **Power Loop Considerations**

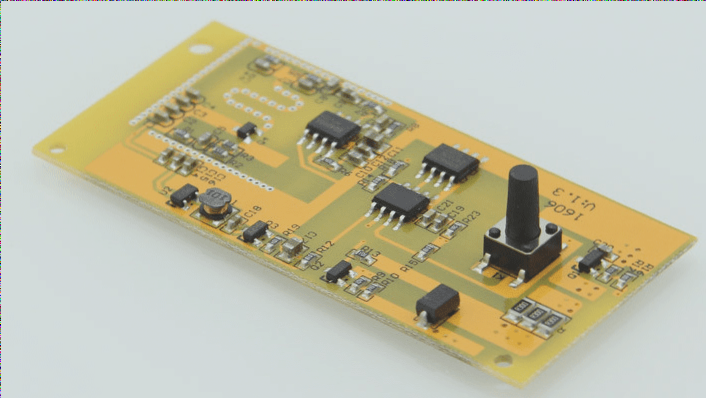

First and foremost, the power board must address the power loop design. In PCB layout, it’s essential to understand the circuit characteristics of the power section. The power supply circuit can mainly be divided into two categories: Di/dt circuits and dV/dt circuits. The layout for these circuits differs significantly.

In a Di/dt circuit, which involves large current changes over short time periods, it is crucial to minimize the loop area of the entire circuit. A smaller loop area helps reduce interference, as it lowers the likelihood of unwanted coupling. In contrast, the focus for a dV/dt circuit is different. This circuit experiences significant voltage changes over short periods, which can generate external interference. Therefore, the copper traces in this section should be kept narrow. While the trace width should still be adequate to handle the current, it should be as small as possible. Additionally, efforts should be made to minimize the overlapping area between layers, and sensitive signal traces in the PCB should be routed as far as possible from these high-speed power traces.

2. When routing the driving section of the PCB, the first consideration should be the area of the entire driving ring. The goal is to keep this area as small as possible, ensuring it is as far as possible from any sources of interference and as close as possible to the driving components.

When powered by components such as MOSFETs, the routing of the gate (G) and drain (D) terminals should not be parallel. This is because, in most cases, the drain terminal of the MOSFET acts as a high-speed DV/DT circuit, while the gate terminal serves as the drive circuit. If these two lines run parallel, the drive signal may become easily interfered with, resulting in operational issues.

III. **Sampling Signals**

Sampling signals, including current sampling, are also crucial in power supply design, as they are directly linked to the control terminals. These signals must be isolated from other signals as much as possible. If feasible, different sampling signals can be routed separately, and it is ideal to assign them a dedicated ground plane at the corresponding locations.

2. **Important Considerations in PCB Layout for Power Boards**

When laying out the PCB for a power supply board, one of the most critical factors is the proper treatment of the ground. Regardless of the board type, grounding is always vital. It becomes even more complex on power boards, as the ground is divided into multiple segments due to the power section and control section. Handling these ground connections appropriately is crucial. From my experience, the key to managing these areas lies in selecting the correct single-point ground node. Since each power supply design is unique, the single-point ground selection will differ accordingly. For example, in low-power photovoltaic inverters, I typically select a bus capacitor and a ground pin for the connection. In such inverters, the ground pin is connected to the switching power supply input via a large current-carrying capacitor. The small current portion of the ground plane connects to the switching power supply’s ground pin. Other areas, such as the crystal oscillator and ground sampling, also require careful attention, and each company may have its own design rules and approaches for handling ground connections. Many of these ground-related concerns are dealt with online in the design process.

V. **Safety Regulations**

Safety is a critical aspect of power supply product design. Different countries and regions have varying safety standards, and factors like environmental pollution levels and altitude can significantly impact these regulations. It is essential to understand the required safety distances at the outset of design. If safety engineers are available, consulting them for more precise guidelines on creepage and clearance distances can be beneficial. Particular attention should be paid to metallic components on the PCB, such as fuses. If a fuse has a non-metallic center, ensure there is no risk of the fuse’s metal contacts touching the PCB, as this could create safety hazards. Always route traces carefully around fuse areas to avoid any inadvertent contact with metallic parts.

VI. **Heat Dissipation**

For systems with relatively high power levels, heat dissipation becomes an important consideration. Before starting the design, it’s crucial to understand the overall heat dissipation strategy, which could involve natural convection, air cooling, or water cooling. Air cooling, whether through forced air or suction, can have a substantial impact on PCB layout, and should be considered when planning the component placement and thermal management strategy.

VII. **Electromagnetic Compatibility (EMC)**

Electromagnetic compatibility (EMC) is another key concern in PCB layout. To minimize electromagnetic interference, avoid abrupt changes in the width of power traces wherever possible. If sharp corners are necessary, ensure they are as smooth as possible to reduce potential impedance mismatches. Power lines should be kept separate from signal lines when feasible. If they must share a trace, ensure they are properly isolated, and it’s ideal for each loop to have its own dedicated routing path.

If your have any questions about PCB ,please contact me info@wellcircuits.com