Now, the electronic processing industry is witnessing a rising trend in one-stop processing services, notably the PCBA OEM model. Customers opting for PCBA OEM only need to provide electronic processing companies with the necessary materials for production and then await delivery, making it a highly convenient option. Today, the editor will discuss “Precautions for PCBA Foundry Materials and Risks Associated with the Foundry Material Model.”

1. Precautions for PCBA Foundry Materials

1. When selecting a PCBA OEM manufacturer, customers should conduct a practical visit to assess the company’s overall situation, particularly its credentials and professional capabilities. To verify formality, it’s important to check relevant qualification certificates, such as ISO9001 quality management system certification. Additionally, customers should thoroughly understand the manufacturer’s expertise in electronic product processing. I personally visited a PCBA manufacturer to inspect the site, focusing on aspects such as the conditions of the SMT patch processing production workshop,

1. Assessing the conditions of the DIP production workshop, the office environment, and the overall morale of the company’s employees is crucial. Customers should also consider the manufacturer’s recent development trajectory. If improvements are evident, this can indicate the manufacturer’s overall strength and suitability for collaboration.

2. To ensure the quality of PCB boards and electronic components from PCBA foundry manufacturers, it’s essential to look at the well-known companies they partner with during the selection process. Identify whether the company is a reputable medium to large enterprise or if it provides comprehensive PCBA solutions for recognized brands. Additionally, analyzing their involvement in current electronic equipment sectors can provide insight into their production capabilities. Visiting the manufacturer to assess their quality management systems and procurement strengths is vital, as well as examining the stability and efficiency of their partnerships regarding delivery times and supply costs.

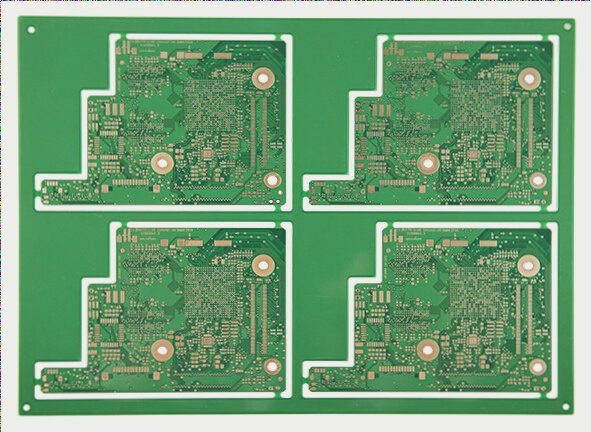

**PCBA Foundry Material**

3. What risks are associated with the OEM model?

1. Confirming material authenticity is challenging.

Since PCBA foundry manufacturers oversee the entire production of electronic components and PCBs, some profit-driven processing plants may resort to sourcing counterfeit or subpar materials to cut costs. Ensuring material quality can be achieved by specifying trusted suppliers and requiring original material certification.

2. The procurement cycle can be unstable.

In the PCBA production cycle, material procurement often proves to be the most variable aspect, particularly when customers require rare components or face high demand. If the foundry lacks inventory, they may need to place orders, leading to uncontrollable delays.

3. Maintenance can be problematic.

If a PCBA foundry manufacturer lacks robust repair capabilities, it can complicate product repairs and extend repair times, ultimately impacting delivery schedules and causing significant losses for customers.

1. Precautions for PCBA Foundry Materials

1. When selecting a PCBA OEM manufacturer, customers should conduct a practical visit to assess the company’s overall situation, particularly its credentials and professional capabilities. To verify formality, it’s important to check relevant qualification certificates, such as ISO9001 quality management system certification. Additionally, customers should thoroughly understand the manufacturer’s expertise in electronic product processing. I personally visited a PCBA manufacturer to inspect the site, focusing on aspects such as the conditions of the SMT patch processing production workshop,

1. Assessing the conditions of the DIP production workshop, the office environment, and the overall morale of the company’s employees is crucial. Customers should also consider the manufacturer’s recent development trajectory. If improvements are evident, this can indicate the manufacturer’s overall strength and suitability for collaboration.

2. To ensure the quality of PCB boards and electronic components from PCBA foundry manufacturers, it’s essential to look at the well-known companies they partner with during the selection process. Identify whether the company is a reputable medium to large enterprise or if it provides comprehensive PCBA solutions for recognized brands. Additionally, analyzing their involvement in current electronic equipment sectors can provide insight into their production capabilities. Visiting the manufacturer to assess their quality management systems and procurement strengths is vital, as well as examining the stability and efficiency of their partnerships regarding delivery times and supply costs.

**PCBA Foundry Material**

3. What risks are associated with the OEM model?

1. Confirming material authenticity is challenging.

Since PCBA foundry manufacturers oversee the entire production of electronic components and PCBs, some profit-driven processing plants may resort to sourcing counterfeit or subpar materials to cut costs. Ensuring material quality can be achieved by specifying trusted suppliers and requiring original material certification.

2. The procurement cycle can be unstable.

In the PCBA production cycle, material procurement often proves to be the most variable aspect, particularly when customers require rare components or face high demand. If the foundry lacks inventory, they may need to place orders, leading to uncontrollable delays.

3. Maintenance can be problematic.

If a PCBA foundry manufacturer lacks robust repair capabilities, it can complicate product repairs and extend repair times, ultimately impacting delivery schedules and causing significant losses for customers.