PCBA Double-Sided Reflow Soldering Process (SMT) and Key Points

- Double-sided reflow soldering is the preferred method in PCB assembly for space optimization.

- Single-sided process can be cost-effective if space constraints are not a concern.

- Precautions are crucial in the double-sided reflow process to prevent component displacement.

Note on Cost Efficiency

While double-sided reflow is common for space optimization, the single-sided process may reduce SMT steps and prove more cost-effective when material costs are compared to labor costs.

Component Placement Considerations

When deciding which side of the PCB to place SMD components during reflow:

- Smaller components are recommended for the first side due to less deformation and better solder paste printing precision.

- Larger or heavier components should be placed on the second side to prevent falling during reflow.

- Special components like BGAs and PIH/PIP components require strategic placement to avoid re-melting and ensure solder quality.

Expert Recommendations

Experts advise careful consideration when placing components on the second side to minimize PCB warping and ensure solder paste control:

- Avoid placing 0201 or fine-pitch components on the second side to reduce the risk of cold solder joints.

- For BGAs, consider using larger solder balls and evaluate the trade-offs between first and second-side placement based on PCB deformation risks.

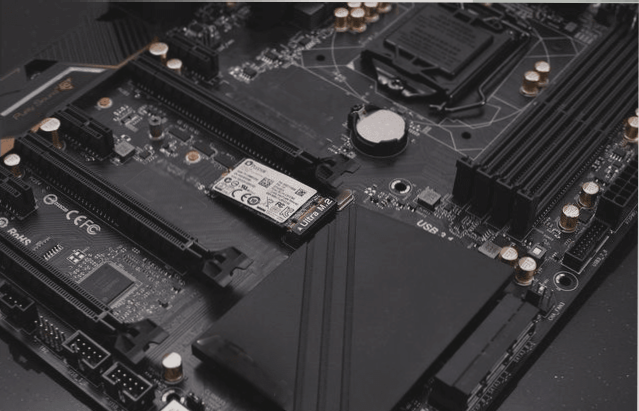

Identifying Components for Processing on PCB Boards

When looking at the front and back sides of an SD card board, it is crucial to be able to distinguish which components should be placed on the first side and which on the second side. This identification is essential for the proper arrangement and processing of components.

PCB Soldering Methods in Mass Production

During mass production, there are various soldering methods used for assembling electronic components on circuit boards. The choice of soldering method is typically determined during the initial design phase, with component placement directly impacting assembly quality and sequence, and layout indirectly affecting efficiency.

Types of PCB Soldering Processes

- Full-Board Soldering: This category includes reflow soldering and wave soldering techniques, where the entire board is soldered at once.

- Partial Soldering: These methods involve soldering only specific areas of the board and include techniques such as carrier wave soldering, selective soldering, and non-contact laser soldering.